Expanding Production Bumps Index Above 50

Index expands for first time since June 2019.

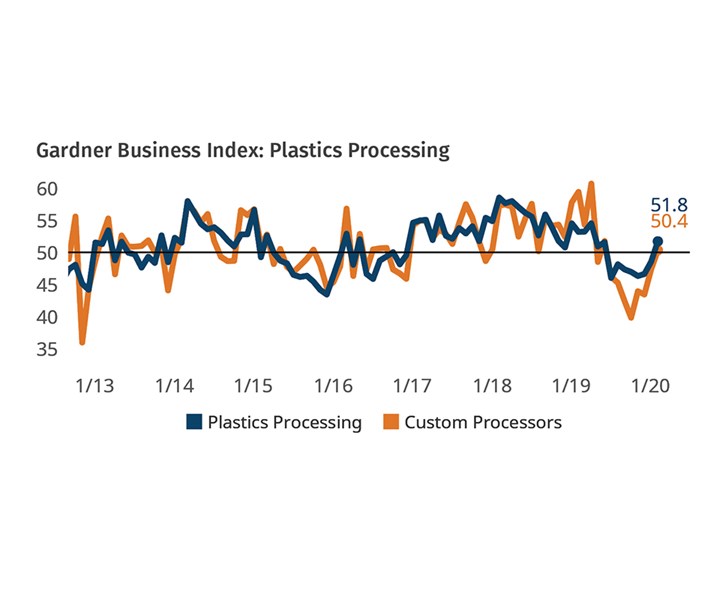

The Plastics Processing Index expanded for the first time since June 2019 with a February 2020 reading of 51.8. (Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The farther away a reading is from 50, the greater the change in activity as compared with the prior month.)

Most of the Index’s components reported improved figures versus the prior month. Gardner Intelligence’s review of the underlying Index reveals that the Index—calculated as an average of its components—was supported by an eight-month high in production activity and a modest expansion in employment. The Index was pulled lower by a sharp contraction in export activity and a ninth consecutive month of contracting backlog activity.

FIG 1 Both indexes expanded in February for the first time since June 2019. Plastics processors reported expanding production, new orders, supplier deliveries and employment activity. This positive news, however, will likely be soon overshadowed by COVID-19’s mounting impact on the global economy.

FIG 1 Both indexes expanded in February for the first time since June 2019. Plastics processors reported expanding production, new orders, supplier deliveries and employment activity. This positive news, however, will likely be soon overshadowed by COVID-19’s mounting impact on the global economy.

Manufacturing Outlook as a Result of Coronavirus

The impact of COVID-19, widely known as the Coronavirus, is expected to have an adverse effect on the Index in the coming months. The necessary efforts of Asian governments in January and February—and by a widening collection of nations in February and March—to combat the spread of COVID-19 are also having a detrimental impact on the world’s supply chain, as workers, companies and cities are affected by quarantine measures. This will most immediately restrict the normal flow of upstream and sub-component goods which are necessary for the proper functioning of the manufacturing sector.

Both the overall Plastics Processing and Custom Processor Indexes are unique in their ability to measureNorth American business conditions on a monthly basis. This means that moving forward these indexes will be able to quantify both the initial shock from the virus along with the timing and strength of the market’s eventual recovery from the economic impact of the virus.

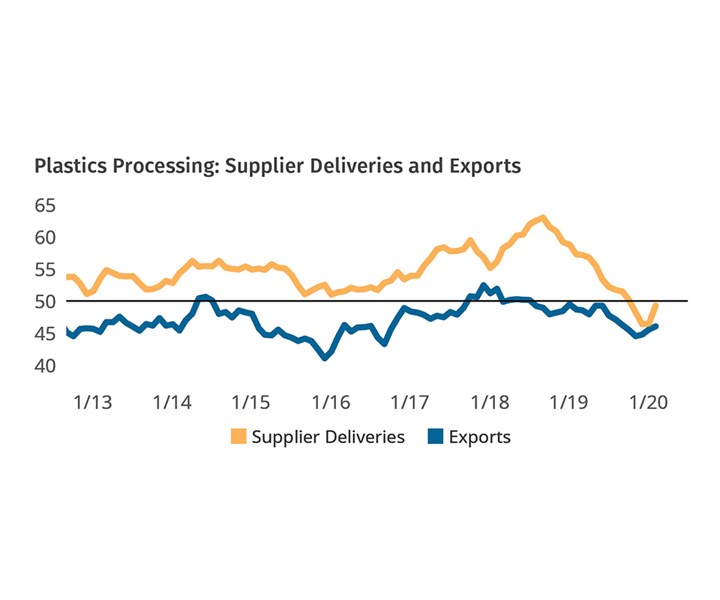

FIG 2 Gardner Intelligence expects that most—if if not all—of its indicators will be subjected to shocks from COVID-19. That the virus originated in Asia suggests that American manufacturers in the immediate future should pay particular attention to their supply chains and expect increased volatility in export orders and material prices.

FIG 2 Gardner Intelligence expects that most—if if not all—of its indicators will be subjected to shocks from COVID-19. That the virus originated in Asia suggests that American manufacturers in the immediate future should pay particular attention to their supply chains and expect increased volatility in export orders and material prices.

As the Index is based on responses to surveys conducted each month by subscribers to Plastics Technology magazine, it is particularly important at this time for our subscribers to complete the GBI survey sent to them each month. Your participation will enable the best and most accurate reporting of the true magnitude and duration of COVID-19. It will allow you and your peers to make data-driven decisions at a time when there may be a strong temptation to make impulsive gut-decisions that could make a difficult situation worse.

ABOUT THE AUTHOR: Michael Guckes is chief economist and director of analytics for Gardner Intelligence, a division of Gardner Business Media, Cincinnati. He has performed economic analysis, modeling, and forecasting work for more than 20 years among a wide range of industries. He received his BA in political science and economics from Kenyon College and his MBA from Ohio State University. Contact: (513) 527-8800; mguckes@gardnerweb.com. Learn more about the Plastics Processing Index at gardnerintelligence.com.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)