Finalists in Process/Assembly Category of SPE Auto Awards

Blow molded spoilers, high- and low-gloss door trim, and 2-shot chrome and paint highlighted in the process/assembly enabling technologies category.

Blow molded spoilers, high- and low-gloss door trim, and 2-shot chrome and paint highlighted in the process/assembly enabling technologies category.

This is the last of my series of blogs on the 2015 SPE Automotive Innovation Awards, focusing on the four finalists in the process/assembly enabling technologies category.

• Blow-Molded Spoiler Assembly: Featured on GM’s 2016 Cadillac ATS V Series, this blow-molded spoiler features a complex, triangular-shaped design and a one-piece construction, while maintaining uniform wall thickness and product integrity. Tier 1 Metelix Products Inc., which also supplied the tooling, blow molded the part using Magnum 1250BG ABS from Trinseo.

Achieving the complex deep-draw features of this part required a three-piece tool with a large slide that extends the entire raw edge of the mold cavity. Timed slide operations enabled the parison to expand with minimal stretch, and laser venting improved air evacuation for wall-thickness control. The final part meets aggressive styling objectives at 10% lower cost and 20% lower weight versus conventional blow molding.

• 2-Shot Selective Chrome & Paint Finish Panels: This is featured on the 2016 Ford Explorer. To meet program direction for a multi-colored finish panel with the same package space (without incremental space for attachments), it required a two-shot selective chrome and paint process in a single-molded piece with similar materials. Tier I suppliers Summit Polymers, Inc. and Lawrence Automotive Interiors Ltd. molded the panel using Cycolac ABS and Cycoloy PC/ABS from SABIC.

In the first shot, the PC/ABS is injected into a dual-cavity tool on a rotary platen. In the second shot, a very-thin plateable ABS grade is overmolded. Dip plating plus masking and painting offer numerous finish options with lower gloss over plating and MIC (mold-in-color) applications. The process achieves a very-good bond, has zero-margin gap, and zero squeak and rattle. A $70,000 savings is realized due to elimination of secondary joining operation, along with a 10% weight reduction due to elimination of joining features.

• Door-Trim Switch Bezel: This MIC application is featured on the 2016 Ford Edge. By combining a heated mold and a special stainless-steel cavity with extra cooling on the grained surface, it was possible to create the look of two parts—one in high-gloss piano black and one in a low-gloss grained surface, in a single tool. This, while achieving impeccable fit and finish and craftsmanship.

Yanfeng USA Automotive Trim Systems molded the part using Ultramid A3L nylon 66 from BASF. This process removed the need to mold multiple parts and/or paint, saved $4/vehicle, and eliminated the VOCs and cost of a painting operation.

• Press Bonding with Edge Folding & CNC Deco Stitch: This is featured in the 2015 Ford F-150 pickup. A combination of high-speed decorative stitching and press lamination with automatic edge folding and wrapping helped bring the look and quality of cut-&-sew and hand wrapping to a high-volume production vehicle.

Faurecia Interior Systems supplied the part using TPO skins from Haartz Corp. This innovative new process combination saves approximately 8 oz. of weight by using the lightweight TPO skins instead of heavier PVC, while also cutting scrap 10%, cycle time 55%, $10/vehicle direct costs, and approximately $1-million dollars in tooling savings.

Search for nearly 100,000 grades of polymers on the Universal Selector by clicking here: http://www.ptonline.com/materials

Related Content

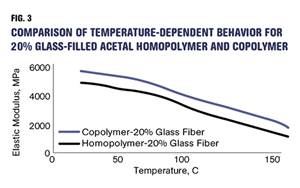

How Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreLanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreWhat is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)