How SABIC Developed a Prototype Solid-State Water Meter Made from Amorphous Noryl PPO to Make an Entry in that Sector

The company has demonstrated that GF Noryl can meet the required mechanical part performance level in injection molded complex parts to compete with incumbent thermoplastics and even brass.

We were recently approached by SABIC on work they have had underway to make an entry with Noryl PPO in the ultrasonic and/or electromagnetic water meter sector, dominated today by metals (brass—70-80%) or higher-end glass-fiber-reinforced (GF) semicrystalline thermoplastics. The latter are often overengineered for the applications but work and provide OEMs with confidence that they will last for 10-to-12 years before replacement is needed.

The company has developed a prototype that can meet the required mechanical part performance level in such injection molded complex parts through the successful ‘marriage’ of material, design and processing technology. Moreover, they say use of their GF Noryl in this application results in cost savings of 15% to 20% over incumbent thermoplastics and >50% for metal. In addition, lifetime expectation of such water meters in 12-to-15 years. Take a look at how SABIC researchers responded to this editor’s questions on why they undertook this project and how they approached it.

Q: What prompted SABIC to initiate this work?

SABIC has been active with its Noryl PPO in the water management space for decades, especially in applications in contact with drinking water, including standard (i.e. volumetric or mechanical) water meters.

With the emergence of new types of water meters (solid-state water meters such as ultrasonic or electromagnetic flow meters), we saw yet another application space where the use of our materials could be beneficial.

These type of meters are growing in popularity as they are more accurate and often have a longer life-time compared to mechanic / volumetric water meters (meaning higher ROI for utility companies). As a result, this market segment is growing fast (in some case >10% CAGR) and there is a lot of demand across all regions/poles.

Currently the incumbent materials of choice are brass or thermoplastic resins such as GF PPA, GF PPS, and GF nylon 12, all of which are premium semi-crystalline materials.This relatively big and fast-growing market with potential for replacing incumbent semi-crystalline thermoplastics or even brass with amorphous Noryl PPO was very attractive to us. As a result we decided to take a different approach to demonstrate to customers that our GF Noryl PPO resins can do the job and bring additional value—such as part savings, compared to incumbent materials.

Q: Was Noryl PPO ever considered previously by anyone for these applications commercially?

Glass-filled PPO such as Noryl WM330G or FE1630PW resins have been considered before by major OEMs in this space, but as a drop-in solution they could not meet the very demanding application requirements, especially concerning fatigue/fluctuating pressure (e.g. water hammer and sinus wave pressure resistance at cold water temperatures).

Since these customers felt Noryl resin was not robust enough, they were also hesitant to develop new parts/models with Noryl PPO in mind. Therefore, we decided to develop our own prototype leveraging our experience and advanced (anisotropic) modelling capabilities to design a solid-state water meter (i.e. flow tube) that would meet the stringent requirements of OEMs and convince them to use Noryl resin.

SABIC researchers took the following approach:

▪ Select 5-6 commercially available solid-state water meters on the market and complete a tear-down of each to understand major components, principle of working, part design and (incumbent) materials used.

▪ Spoke to several key OEM’s and thought leaders in this space to understand their specific needs and requirements for this application, especially when it comes to long-term mechanical properties such as fatigue, burst and creep rupture.

▪ Based on the above, they designed/developed their own prototype to meet these requirements based on advanced simulation capabilities leveraging proprietary data

Q: How did Noryl measure up to existing high-performance engineering resins used for this application:

As mentioned previously, because Noryl is an amorphous resin, fatigue performance can be an issue. In order to meet the part / OEM requirements we had to focus on developing a balanced/optimized part and tool design. The influence of processing parameters was investigated for the application’s long- term performance to ensure optimal molding.

We positioned a 30% GF Noryl PPO (i.e. Noryl WM330G) as an offset to the incumbent 40% GF PPA or GF PPS or 50% GF nylon12. The overall strength of Noryl resin is good dimensional stability when in contact with water and temperature; good resistance against drinking water over long periods of time; and very low water uptake with no change in properties due to water uptake. Noryl resin also exhibits a good constant pressure resistance (creep rupture). Furthermore, it demonstrates easy processing. Also, not widely known is that Noryl has excellent anti-bacterial growth properties. Additionally, the low material density makes is attractive from a cost point of view.

Q: Can you elaborate on the key results?

After we developed a prototype and cut the tools, we molded water meters (i.e. flow tubes) from different materials, including Noryl WM330G resin, to compare their performance, The first and most important step was to convince OEMs that our materials are able to meet the threshold requirements. In certain cases, attention was needed for correct processing conditions/parameters to obtain the best performance but eventually we were able to show that 30% GF Noryl resin can meet the threshold requirements.

Because these parts are installed on existing infrastructure where unexpected stresses could occur (i.e. due to misalignment of pipes or simply the way these meters were installed), we had to perform additional internal tests to prove that Noryl WM330G resin would not fail due to incorrect installation. The successfully executed tests were related to bending the water meter (i.e. flow tube), pulling it in opposite directions (i.e. similar to tensile bar test), and also testing the strength of the threaded connection with a torque test.

We have shared results with several OEMs and they were positively impressed by the work and significant improvements in performance that resulted by just making the right design decisions for both the actual part and tool (design), and optimizing processing conditions. Several of them have tried Noryl resin since then and will consider it for future projects, especially where they have more design freedom as current tools are designed for semi-crystalline materials.

Meanwhile, SABIC researchers elaborated further on the key challenges and how they met them. One of the biggest lessons learned was how optimizing processing/injection molding parameters but also certain mold design decision (e.g. hot vs. cold runner) can significantly improve part performance. Noryl is amorphous and therefore weld line strength is its Achilles heel. To achieve best part performance, and hence create strong weld lines as well as avoiding voids, they aimed at:

▪ Higher melt temperature: 330 C/626 F (vs 290 C/554 F-310 C/590 F on datasheet)

▪ Higher mold temperature: 120 C/248 F (vs 100 C/212 F on datasheet)

▪ Higher packing pressures: 900 bar (e.g. not ~60% of injection pressure, now ~250%)

▪ Longer packing times: e.g. 30 sec (should not be limiting factor)

▪ Hot runner vs cold runner: hot runner prevents premature gate freeze and therefore longer and more efficient packing pressure can be applied to avoid void formation during cooling. In case of cold runner, there’s a need for a sufficiently large sprue.

▪ Often we see too low a packing pressure and too short packing times. Packing should not be a limiting factor; packing and cooling should happen simultaneously within the total cycle time. Note, gate freeze (with cold runner) might prevent sufficient packing times.

▪ Recommended set-up process:

1. 99% fill w/o pressure

2. Determine appropriate injection speed

3. Set appropriate packing pressure & time

The above improvements helped the SABIC team better fill the part (i.e. 99% of hypothetical mass) and reduce voids that might lead to failures and improve mechanical performance requirements, such as burst and fatigue.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

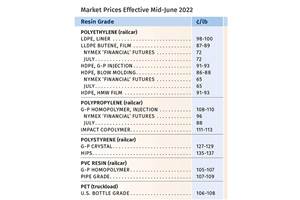

Read MoreVolume Resin Prices Move in Different Directions

PE, PP, PVC, and ABS prices slump, while PS, PET, PC, and nylons 6 and 66 prices rise.

Read MoreWhat is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

Read MorePrices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More