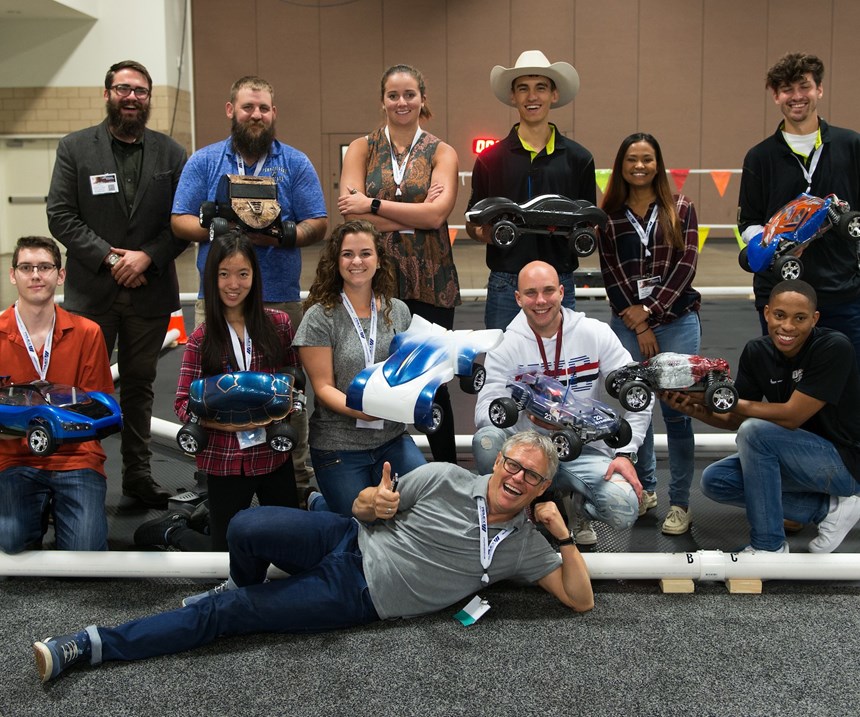

Inaugural Student Radio Controlled Car Race & Design Competition

SPE’s Thermoforming Division announced the winners of this first-time event.

In this first-of-its-kind competition held by the The Society of Plastics Engineers (SPE) Thermoforming Division, the winners have been announced.

The competition’s goal was to encourage students to consider a career in thermoforming by engaging them in a fun design project, according to Mark Strachan, former SPE Thermoforming Division Chair and organizer of the Student RC Car Race and Competition.

“The students’ enthusiasm for this project was contagious, and it was especially rewarding to see the students forging those all-important connections with their corporate sponsors. We expect even greater student and corporate participation in future competitions.”

Students from six schools in the U.S. and Germany were charged with designing, manufacturing and decorating the bodies of radio controlled cars furnished by the division with support from corporate sponsors. The car body had to be formed using clear plastic, such as PET, PETG, acrylic or PC, and produced using the vacuum/thermoforming process.

Students also participated in a race conducted on a built-to-specification indoor racetrack located on the exhibit hall floor during the Thermoforming Division’s annual conference, held September 24-26 in Fort Worth, Texas.

Cash prizes were awarded in three different categories: People’s Choice, Best Design and the race itself. This year’s winners are:

● People’s Choice; Best Design; and First Place in the Race: Ryan Fuller and Karina Patricia, both of Georgia Tech.

●Second Place in the Race: Max Schoch, ILLIG Apprentice Program.

Related Content

-

Resin Prices Still Dropping

This downward trajectory is expected to continue, primarily due to slowed demand, lower feedstock costs and adequate-to-ample supplies.

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

The Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

.png;maxWidth=300;quality=90)