Ineos Styrolution Talks Closing the Loop on Polystyrene

The company is collaborating with several companies on several solutions, including depolymerization.

In the past couple of years, global styrenics supplier Ineos Styrolution has made a number of advancements in closing the loop on polystyrene and other single-use products.

In this Q&A, Cassie Bradley, sustainability and circular economy manager at Ineos Styrolution, talks about the company’s work in this area, increased demand for recycling content and some of the key recycling processes that Ineos is evaluating.

Can you talk about the company’s work to close the loop on polystyrene and single-use packaging?

Ineos Styrolution has a multi-faceted [holistic] approach to closing the loop on polystyrene. We are collaborating with several companies developing innovative solutions such as polystyrene (PS) depolymerization, a form of advanced recycling. We have found that advanced recycling plays into Ineos Styrolution’s existing strengths in styrene monomer conversion, and we’ve been able to bring this knowledge into our partnerships as we work together to scale up these innovative technologies for the benefit of consumers and society. We are also working to educate on the inherent properties and attributes of polystyrene that already make it such a sustainable option, such as the strength to be thin and lightweight, and energy efficient.

When did the company get involved with recycling?

Sustainability has long been in our line of sight at Ineos Styrolution. Throughout the last five years as market demand has grown, we have been able to play a leadership role in building solutions toward a closed-loop system. We formed a recycling consortium with Pyrowave in 2017 and signed our JDA with Agilyx in that same year. We announced our JDA with GreenMantra in 2019. We continue to be diligently focused on moving these partnerships forward while continuing to explore other innovative opportunities the market is creating.

What were some of the issues with recycling polystyrene in the past? How are those being overcome now?

We are seeing a real increase in interest for this material in the market, both from our direct customers as well as from consumers in general. In fact, polystyrene has actually been mechanically recycled for many years, and depolymerization was developed as far back as the mid twentieth century. Increases in demand for recycled content are driving an upward surge of investment and innovation.

What are some of the key recycling processes that Ineos is evaluating? Which recycling companies are you partnering with?

By leveraging multiple types of technologies, both new and existing, our communities can ensure that the widest possible range of polystyrene is recycled in the most efficient way. For instance, mechanical recycling offers a mature technology with low greenhouse gas (GHG) impact, whereas depolymerization can process light contamination in feed streams and yield virgin-based quality outcomes. In this way, using both solutions together can be complimentary. We’ve entered into partnerships with several companies such as Agilyx and Indaver to expand in advanced recycling technologies, Unternehmensgruppe Theo Müller to develop recycled PS yogurt cups, and Tomra to study PS sorting efficacy.

Has the COVID-19 pandemic had an impact on the company’s work with recycling PS?

COVID-19 has shown how valuable polystyrene and single-use products are in keeping us safe and healthy. These products bring great value to our economy and our society. The current situation emphasizes how important it is to bring a circular pathway for these materials to market, so that we can continue to enjoy their numerous benefits and protections, which expand far beyond the current pandemic.

What opportunities and challenges do you see with regards to bringing the recyclability of PS to a larger and more global scale?

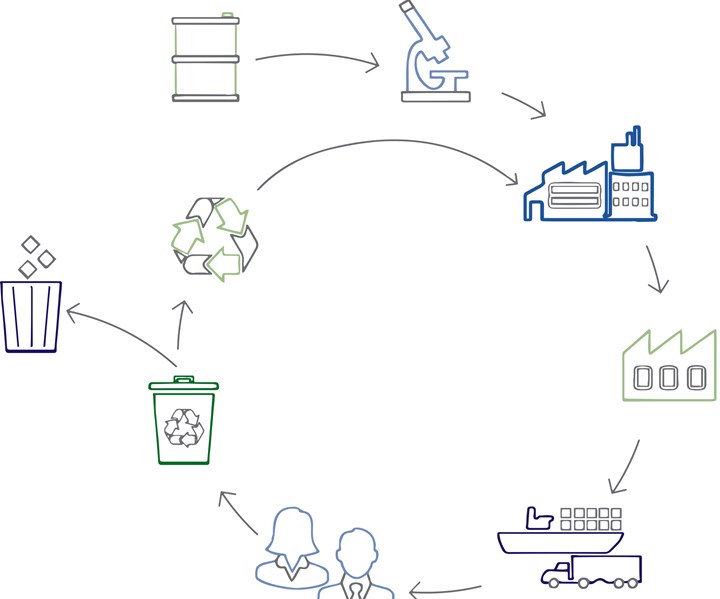

It is truly the nature of a circular economy concept that no one can achieve it alone. Each phase of the loop from production to end consumer has a critical role to play. Continued support of recycling and the use of recycled content in products and packaging from the public is crucial. In addition, cooperation between legislative and corporate bodies is needed to identify and implement continued optimizations in policy and infrastructure.

Circular economy graphic.

Read Next

Leading the Charge: Brand Owners Moving to Boost Recycled Content in Packages, Products

Leading brand owners and a big-box retailer discuss their recycling goals, which will impact processors and the entire supply chain.

Read MoreAgilyx: Recycling Must Continue Operating During the Coronavirus Pandemic

Agilyx CEO Joe Vaillancourt discusses the status of the company's operations and the importance of recycling during the COVID-19 pandemic.

Read More

.png;maxWidth=300;quality=90)