Is a robotic revolution underway in China?

Robots have helped U.S. manufacturers better compete with China, now Chinese plants are integrating automation to boost their own productivity.

China was the second largest destination for industrial robots in 2012, with sales in the People’s Republic increasing an average of 25%/year from 2005 to 2012, according to the International Federation of Robotics 2013 World Robotics report.

Guangzhou, the epicenter of much of China’s plastics processing, is planning to build two to three “robot industrial development zones”, according to a China Daily article, appropriately headlined: Guangzhou to invest in robots.

In that article, a government official stated that more than 80% of manufacturing operations in Guangzhou would be using industrial robots by 2020, reflecting a period of “explosive growth.” Yi Ming, deputy director of the Guangzhou commission of economy and trade, added that at 30% demand growth, the capital of Guangdong Province was outpacing China’s overall interest in robotics.

Western suppliers look East

As a I researched an article on robotics within plastics processing for a special Industrial Automation supplement produced by PT’s publisher, Gardner Business Media, China emerged as a recurring theme.

My interview with Helen Ke Feng, global industry segment manager, plastics and rubber, at ABB was delayed as she traveled throughout Asia, spending two weeks in the region, noting that the her biggest demand growth came from the Chinese market.

Jean-Michele Renaudeau, managing director of Sepro, said his company is closely watching China. “We are optimistic about the future of Sepro in China,” Renaudeau said, adding that since salaries have been volatile, and increasing, a one-time investment in a robot can allow Chinese processors to stabilize production cost.

Beyond that, the Chinese market, like any market, sees the repeatability benefits that robotics can bring to a process. “Even in an emerging country like China,” Renaudeau said, “you see the exact same tendencies. There is a clear trend towards more robots because automation is the key for productivity, it is the key for quality.”

Jim Swim, business manager at custom automation supplier CBW, has seen interest in his company’s systems flow both ways: U.S. shops automating to meet increased production requirements due to reshored work, and Chinese molders automating to increase quality and lower costs as labor prices increase.

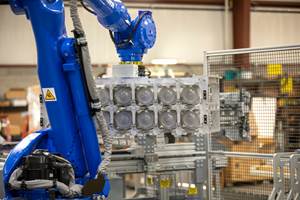

“It used to be that China just had to throw a lot of labor at a project,” Swim said, “but they’ve had to evolve into more automation.” When I visited CBW, one of the cells on its production floor was going through final testing before shipment to China. Swim said CBW has sent a few cells to China over the years, with the vast majority of its projects still in the U.S., and more to come if China doesn’t automate.

“The markets that have been used for China, like packaging, that used to be so much more cost effective,” Swim explained, “are not as cost effective anymore.”

At Chinaplas earlier this year in Shanghai, I asked Werner Wittmann, founder of what is now Wittmann Battenfeld, about the Chinese automation market. Wittmann was an early mover in China, adding production there in 2005. Over the last 8 years, Wittmann said that as labor costs rise in the country, there is greater pressure to automate. Today, there’s a focus on higher automation technology, with a switch from pneumatically driven to servodriven systems.

In March, one month prior to Chinaplas, German robot manufacturer KUKA Roboter GmbH opened a brand-new, 20,000 square meter production facility in Shanghai, with an annual capacity for up to 5000 robots. At the time, Till Reuter, CEO of KUKA AG, noted:

China is the world’s largest and fastest-growing robot market. We have a longstanding partnership with many renowned Chinese customers. In order to accommodate continued growth, we have now significantly increased our capacity in Shanghai.

An expectation for reliability

KUKA’s systems, just like ABB’s, Sepro’s, CBW’s, and Wittmann’s, will be priced to reflect their value. Today, Chinese processors have little choice but to pony up, with 90% of the robots purchased in China imported in, according to Guangzhou’s Ming. The government is hoping to address that with greater domestic supply, as noted in the China Daily article, but Sepro’s Renaudeau, for one, is still optimistic about the long-term prospects for Western robotics suppliers opportunities in China.

“There is a clear demand or expectation for reliability; it's a new philosophy for the Chinese market,” Renaudeau said. “The Chinese market will be very similar to the U.S. or European markets within a few years. You cannot afford to have molding machines or robots that are not being served, with the absolute guarantee that you have a partner that will be there.”

Related Content

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More