MIT Makes Strides in Future of PHA-Based Biopolymers

Researchers identify key enzyme that can be tweaked to make it more industrially useful.

Researchers identify key enzyme that can be tweaked to make it more industrially useful.

Biopolymers like PLA and PHA are here to stay and expected to continue to evolve. The latter, polyhydroxyalkanoates or PHAs, are linear polyesters produced in nature by bacterial fermentation of sugar or lipids. Produced by the bacteria to store carbon and energy, PHA can be combined with a large number of different monomers to produce biodegradable plastics with varying properties.

PHAs generally have had more of an uphill battle in terms of commercial advancement, with companies such as Metabolix, Woburn, Mass., recently exiting the business with its sale to Korea’s food and bioengineering conglomerate CJ CheigJedang. In the last couple of years, Metabolix had shifted its focus to promoting it amorphous PHA (a-PHA) for use as a performance additive for PVC and PLA.

In contrast, MHG, Bainbridge, Ga., became the world’s largest producer of PHA biopolymer with the startup of its first commercial-scale fermenter last year. Initial capacity for Nodax PHA is 30 million/lb/yr, though at full production, the plant is capable of twice that volume. The company’s PHA-based resins, which include hybrids such as PHA/PLA, have been targeted for use in such articles as: bottles for beverage, personal care and household products; food packaging and service items such as cups, lids, containers and utensils; bags for shopping, trash collection and composting; agricultural mulch and fishing lures; healthcare bandages, tubes and syringes.

Now MIT chemists have determined the structure and mechanism of the PHA synthase enzyme, present in nearly all bacteria which use it to produce large polymers that store carbon when food is scarce. The bacterium Cupriavidus necator can store up to 85% of its dry weight as these polymers.

And the key is that the PHA synthase enzyme produces different types of polymers depending on the starting material, usually one or more of the numerous variants of a molecule called hydroxyalkyl-coenzyme A, where the term alkyl refers to a variable chemical group that helps determine the polymers’ properties. Some of these materials form rigid plastics, while others create softer and more flexible plastics or ones that have elastic properties, which are more similar to rubber—all very similar to petroleum-based thermoplastics but with biodegrability.

The MIT team notes that PHA synthase is of great interest to chemists and chemical engineers because it can string together up to 30,000 monomers, in a precisely controlled way. “What nature can do in this case and many others is make huge polymers, bigger than what humans can make…and, they have uniform molecular weight, which makes the properties of these polymers distinct,” says JoAnne Stubbe, the Novartis emeritus professor of chemistry and a professor emeritus of biology, who along with MIT professor of chemistry Catherine Drennan, are the senior authors of the study, published in last month’s Journal of Biological Chemistry.

It appears that these two, along with other chemists, have aimed to identify the PHA enzyme’s structure for over 20 years, but it had, until now, proven elusive because of the difficulty in crystallizing the protein. Crystallization is a key step to performing X-ray crystallography, which reveals the atomic and molecular structure of the protein.

Crystals at hand, the MIT researchers collected and analyzed the resulting crystallographic data to come up with the structure. The analysis revealed that PHA synthase is made up of two identical subunits, which form what is known as a dimer. Each of them has an active site in which the polymerization occurs—this debunked an earlier proposal that the active site is located at the dimer interface.

Also key in this analysis is that the enzyme has two openings—one, where the starting materials enter, and another that allows the growing polymer chain to exit. Says Stubbe, “The coenzyme A part of the substrate has to come back out because you have to put in another monomer…there are a lot of gymnastics that are going on, which I think makes it fascinating.”

The next step, according to Drennan, is to try to solve structures of the enzyme while it is bound to substrates and products, which ought to result in more information critical to understanding how it works. “This is the beginning of a new era of studying these systems where we now have this framework, and with every experiment we do, we’re going to be learning more.”

While the structural information that resulted from this work will have little impact on the cost of producing PHA polymers, the researchers see potential for the production of new and improved materials with unique properties.

Related Content

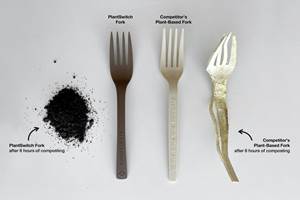

Advanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)