Nine “Shots” Plus One Machine Equals a Unique LSR Molding Tech

How'd they mold that? One iPhone case composed of nine distinct LSRs molded on a single machine.

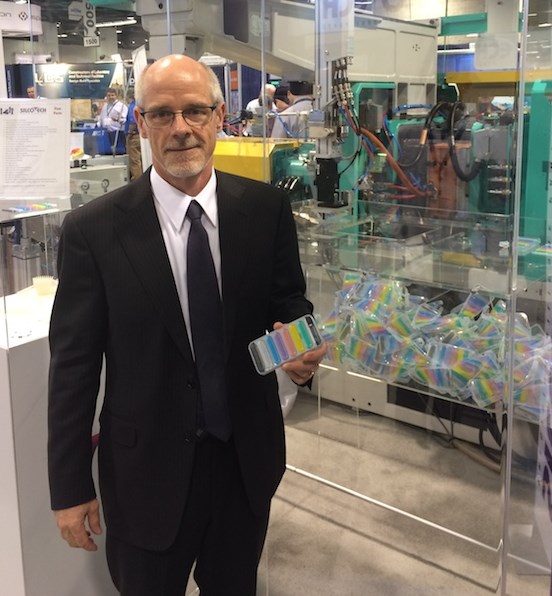

How did this part come out of that machine? Visitors to liquid silicone rubber (LSR) molder Silcotech’s MD&M West booth were genuinely perplexed by the nine-shot iPhone cover molded on a by-all-appearances single-shot Arburg Allrounder 370A. Eying the material-feeding system, featuring the standard two barrels of LSR ingredients, a visitor pushed Silcotech President Michael Maloney on the “how” of his novel display, and he coyly replied, “That’s the magic.”

The magic result? An LSR iPhone cover composed of nine distinct LSRs, with eight different shades of LSR down the back, and each of those different colors featuring a unique durometer from 20 to 75 Shore A, plus another LSR for the phone case’s housing.

Maloney said Silcotech has been developing the technology it’s codenamed “Canvas” for the last 18 months, collaborating closely with LSR supplier Dow Corning. That company’s QP1-2XX series LSR was applied, with it also making its debut at the show, according to Gary Lord, Dow Corning’s global strategic marketing director for healthcare. The high-flow LSR also features a low compression set and good green strength allowing it to demold without damage, as well as having the ability to create intricate parts.

In operation, the mold’s “B” side featured a rotary plate, with the eight discrete durometer/color strips molded in the first “shot” on the bottom half of the tool, which then rotates 180 degrees for the housing to be molded in the second shot. An Allrounder 370A molds the 20.5g part in a cycle time of 57 seconds from a 1+8 cavity tool.

Maloney said Silcotech designed the specialized material handling, injection systems and cold deck on the cell. Going forward, the company will keep the technology as a closely held trade secret, with the goal being to keep the novel concept under its own roof while using it to make parts for customers.

“We’re working on a number of projects right now that use 3, 4, or 5 shots,” Maloney said, adding that the technology creates a “larger canvas” for designers. “It’s demonstrating the possibility of integrating shots, breaking down the perceived barriers. There’s not a single LSR device that couldn’t benefit.”

The same cell will be on display at NPE2015 at Silcotech’s booth (W7253; pictured below, Michael Maloney with the 9-shot LSR iPhone case).

Related Content

-

Datwyler Expands O-Ring Production

The company has added injection molding machines to production sites in Mexico and China to boost production.

-

LSR Machine and Injection Unit Designed for Low-Shot Volumes

BOY will present its XS machine running an LSR application created in collaboration with the University of Kassel at DKT 2022 (June 27-30; Nuremberg, Germany).

-

Semperit Acquires Rico Group

The global maker of specialized polymer products for industrial applications, including hoses and belts, has purchased the Austrian headquartered liquid silicone rubber molder and moldmaker.