No Major Production Cutbacks of Material or Downstream Products Yet

Production at resin suppliers and plastics processors still going strong in the first week of fast-paced coronavirus life disruptions.

In view of the fast-paced life changes/disruptions taking place across the country due to the coronavirus pandemic, particularly starting this week, I reached out to a handful of industry sources, including a custom injection molder; a leading molder of HDPE and LDPE caps and closures for the dairy and water bottle market sectors; a major thermoformer; a compounder of engineering thermoplastics; and resin-pricing consultants. These initial responses to whether production—ranging from materials to downstream plastics products—is being scaled back appear to show the opposite. This is particularly the case in the major packaging market sector ranging from film wrap to food packaging to healthcare packaging. Due to the fluidity of the situation we are all in, these sources preferred to stay anonymous.

Image of coronavirus from the CDC.

A source at an 8-year-old custom injection molder that focuses on product development needs of entrepreneurs and small-to-medium sized businesses, ranging from consumer goods to medical devices said, “We are taking appropriate sanitary measurements and we will continue our production throughout the pandemic.”

A molder of caps closures closures for dairy and water bottles was asked what steps had been taken in response to the virus. The source noted that the company is an SQF/FDA facility which has always had in place policies and procedures to defend their products from any biological contamination. This source said the company hasn’t yet, nor does it expect to cut back production, noting, “We are an essential product to the food industry.”

A source at a major thermoformer of consumer goods—particularly food packaging containers as well as durable goods ranging from tractor hoods to refrigerator components, says the company is implementing all CDC and WHO recommendations. “This includes not having vendor visits, and unless urgent, no travel. Employees that have traveled to ‘high-risk’ places are asked to work from home for a couple of weeks.” Regarding production, this source noted that the first quarter is ending with a barely noticeable softness in their durable goods business. In contrast, their consumer business has been going strong. “Also, we have had no raw material supply problems, as our supplier sources are all domestic.”

A key source at a compounder of engineered thermoplastics whose portfolio also includes ‘near-to-prime’ recycled versions, notes, “So far, our supply chain has not been affected by this situation, and we are not aware of any supply bottlenecks with regards to raw materials. On the customer side we have also not been made aware of any production shutdowns in North America. So far, our own production capabilities are not impacted either, but we have issued a special code of conduct, and most of our office staff work from home.”

Inquiries to a few select resin-pricing consultants yielded largely similar scenarios. None has heard of any shutdowns regarding resin suppliers and/or processors. Moreover, they have seen the opposite—particularly for the entire packaging sector. Said one source, “Most processors say they are very busy… food and medical packaging is going strong. To get empty shelves restocked, we are certain to see a shift in production to the basics--essentially a limit to the variation of foods and other products within a brand (e.g., you may not see five different flavored Doritos).”

Processors, compounder report no raw material supply issues.

These sources also do not anticipate resin suppliers shutting down production, noting that the process of shutdown and restart of reactors is very costly. Still, another source said the industry might see production scaled back 40-45% plant utilization rates, as was experienced in 2008-2009. “This will depend on processors’ business priorities who may also realize opportunities for some resin price concessions.”

Added another source, “I can see concern from some processors of not having enough people to run their manufacturing plants to get product out—all sorts of unexpected consequences could arise. Also, as opposed to packaging, you may expect processors making seasonal products such as those sold in sports arenas and other big venues slowing down.”

Meanwhile, The Plastics Exchange’s CEO Michael Greenberg reported the following in his latest market update, “Notwithstanding the terrible situation for those directly involved with the virus, and we hope it will all clear up quickly, of course many businesses will still continue to operate. There are products that need to be made, and for that, plenty of resin pellets will still be processed. That said, by Wednesday our phones began to ring with orders and while we all recognized the negative change to sentiment, nobody was truly expecting that North American resin prices would quickly vacuum a dime lower. We did not see any panic selling and there were no cargo ships full of resin offered to just anyone who would venture a paltry bid. In fact, the highly resilient North American resin market continued on tightly supplied, but with a very cautious tone.”

Related Content

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

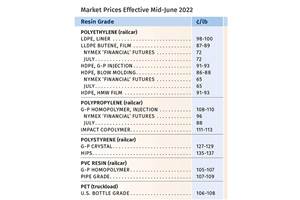

Read MoreVolume Resin Prices Move in Different Directions

PE, PP, PVC, and ABS prices slump, while PS, PET, PC, and nylons 6 and 66 prices rise.

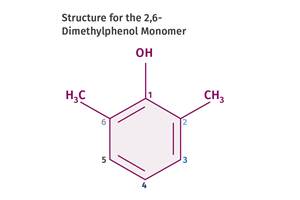

Read MoreTracing the History of Polymeric Materials: Polyphenylene Oxide

Behind the scenes of the discovery of PPO.

Read MoreTracing the History of Polymeric Materials: Aliphatic Polyketone

Aliphatic polyketone is a material that gets little attention but is similar in chemistry to nylons, polyesters and acetals.

Read MoreRead Next

Updated—Coping with Coronavirus: One Blow Molder’s Response

Confer Plastics is pulling out the stops to make and ship products before a state-mandated shutdown.

Read MoreWSJ Calls for Reversal of Plastic-Bag Bans

Journal says plastic bag ban backfires. Calls reusable bags “notoriously dirty and may spread the (Corona) virus.”

Read MoreCoronavirus and the U.S. Plastics Industry Supply Chain

While we cannot confirm today that the coronavirus has already impacted the U.S. plastics industry supply chain, it is reasonable to expect that if the coronavirus crisis in China continues and escalates, it will negatively impact the U.S. plastics industry. For business continuity reasons, U.S. plastics companies need to look at their current supply chain involving China and—as a precautionary measure—examine alternative supply sources.

Read More

.png;maxWidth=300;quality=90)