Nova Chemicals Talks Recycled Plastics, Sustainability Strategy

In this Q&A, Monika Kleczek, circular economy market development manager, Nova Chemicals Polyethylene Business, talks about the company’s efforts to expand a market for recycled plastics.

Monika Kleczek, circular economy market development manager, Nova Chemicals Polyethylene Business.

Nova Chemicals recently published its 2019 Sustainability Report, which highlights its efforts to create a plastics circular economy.

I checked in with Monika Kleczek, circular economy market development manager, Nova Chemicals Polyethylene Business, to learn more about the company’s efforts on plastics recycling and how its working to build a market for post-consumer material.

What are some of the key takeaways in the 2019 sustainability report?

We highlight five key accomplishments in our 2019 report:

- We became a founding member of the Alliance to End Plastic Waste

- We launched seven innovative ready-to-recycle resins

- We reduced our greenhouse gas intensity company-wide by 4% in the last five years

- We strengthened our commitment to zero pellet loss by pledging support to Operation Clean Sweep Blue

- We achieved our lowest recordable injury rate in 10 years

In the press release, it mentioned that Nova is using its expertise to design plastics resins to expand a market for recycled plastics. Can you detail some of the ways the company is working to expand the usage of recycled plastics?

Fully adopting a plastics circular economy requires work across a number of areas, and the participation of everyone in the plastics value chain as well as government, NGOs, and our citizens. We are collaborating with different players on a wide range of initiatives to help advance circularity, which must include expanding the use of recycled plastics:

- Development of the ready-to-recycle family of resins as described in question No. 3 below.

- Application development on existing packaging as well as new packaging structures to accommodate high levels of post-consumer recyclate. All while retaining their desired properties and properly protecting its contents.

- Active participation with industry associations that are working to advance the circular economy. We are serving on committees or boards of organizations including APR, SPC, AEPW and Project STOP .

Can you give a highlight of the seven PE ready-to-recycle resins? Are these currently being used in applications?

Our ready-to-recycle resins are engineered to offer two significant benefits that help build markets for post-consumer polyethylene products:

- As virgin resins, each can be used in packaging film structures in combination with a high percentage of recycled content

- After mechanical recycling, the resins retain balanced physical properties such as tear and stiffness, excellent processability on film and packaging lines, and seal and toughness to provide optimal product protection.

Many brand owners have made commitments both for recyclable packaging and incorporation of a percentage of recyclate in their packaging. Our resins are particularly valuable as companion virgin film content. Used as virgin content, the ready-to-recycle resins compensate for often degraded physical performance of recycled content in film structures, suppressing odor up to 80% and improving optics by up to 15%.

We are selling the ready-to-recycle products commercially into a variety of applications including stretch film, stand up pouches, multipack collation shrink and heavy-duty sacks.

How does the recycling market look this year—is COVID-19 having an impact on obtaining the waste plastic or any other recycling operations?

Our areas of particular focus around the plastics circular economy and product sustainability as detailed in our response to question 5. Plastics recycling is a key component to fully realizing the post-use value of plastics. We still have much to learn on this topic, but following are some thoughts based on what we know and what we’re seeing in the media.

The recycled plastics markets are going to be pressured by prime prices for at least the next two years.

Predating COVID-19, we need investment in recycling technology and infrastructure to improve sorting, cleaning and more generally the quality of recyclate so that it is more comparable to virgin.

We’re seeing changing conditions in mechanical recycling related both to the pandemic and to changing pricing dynamics as a result of oil prices and polyethylene supply.

According to IHS Markit, the recycled plastics markets are going to be pressured by prime prices for at least the next two years. Additionally, recycled plastic pricing cannot fluctuate as easily as virgin pricing. Whether virgin prices are high or low, the cost of producing high-quality recycled pellets remains largely the same. Despite this, some recyclers are seeing a demand increase, for example KW with its natural rHDPE offering (source Resource Recycling).

When COVID began in North America, the momentum for recycling collection paused, and in some cases, collection decreased due to suspensions of curbside programs and container deposit redemptions, in order to keep employees safe and prevent the spread of the virus. However, most facilities now are back up and running at the same capacity as pre-COVID (source Resource Recycling).

Recycling operations have not necessarily changed, but there’s been a volume shift from industrial applications towards packaging for essential products and a focus on responding to current market conditions due to coronavirus.

Can you detail some of the other ways the company is working toward a circular economy?

In May of this year, we announced the JDA with Enerkem to research and develop a new advanced recycling technology. Advanced recycling is a critical technology to capture the value of post-use plastics that cannot be economically recycled mechanically.

We have four key circular economy priorities:

- Plastics recyclability

- Plastics collection

- Post-consumer resin options

- Advanced recycling and recovery

In addition, we work with our customers to optimize their applications’ sustainability in several ways:

- Reducing the amount of plastic material needed in an application through innovative resin architecture and new film structures

- Reducing material and energy consumption during new application development through our proprietary BONFIRE film development program

- Enabling food and other product waste reduction through packaging integrity and barrier performance

- Recyclable packaging, including our moisture and moisture + oxygen barrier film structure designs.

Stay tuned for more exciting announcements in the coming months.

Related Content

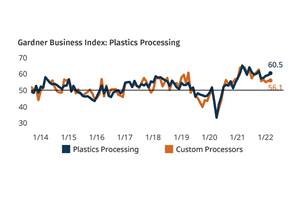

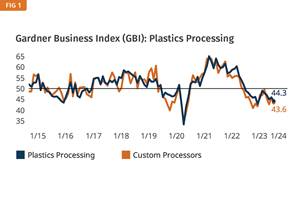

Plastics Processing Contracts Again

October’s reading marks four straight months of contraction.

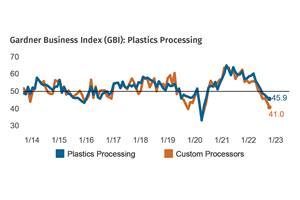

Read MorePlastics Processing Contraction Continues

Contraction dominated the GBI index for overall plastics processing activity and almost all components, collectively suggesting a slowdown.

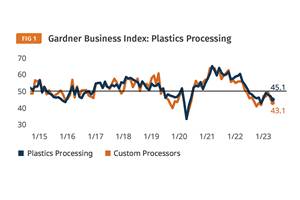

Read MorePlastics Processing Business Index Contracts Further

All components dip as index hits low point of 2023.

Read MoreRead Next

Leading the Charge: Brand Owners Moving to Boost Recycled Content in Packages, Products

Leading brand owners and a big-box retailer discuss their recycling goals, which will impact processors and the entire supply chain.

Read MoreWhat Is the Circular Economy?

In this video from K 2019, hear NOVA Chemicals, TOMRA, Covestro, Rapid Granulator and SABIC each discuss plastics’ role in the circular economy.

Read MoreK 2019 Preview: Resins & Additives for Sustainability in Cars, Electronics & Packaging

Material suppliers are committed to the ‘Circular Economy,’ as evidenced by their adoption of new technologies, product introductions and collaborations.

Read More