Panel of Pros to Discuss Automotive Design Trends at GPS 2016

Analysts, industry leaders and plastics manufacturers will address expanding use of plastics and composites at this year’s IHS Markit and SPI event.

Analysts, industry leaders and plastics manufacturers will address expanding use of plastics and composites at this year’s IHS Markit and SPI event.

At the upcoming (Sept. 28-30, in Chicago), GPS 2016: The Global Plastics Summit, hosted by IHS Markit and SPI, attendees will be treated to a panel of industry pros that will address the expanding use of plastics and composites in automotive design. (Last month, Denver-based IHS merged with England’s Markit Ltd. into a global information giant, IHS Markit, headquartered in London.)

Chemical researchers at IHS Markit report that by 2020, the average car will incorporate nearly 350 kilograms (771.63 lbs) of plastics, up from 200 kilograms (440.92 lbs) in 2014. This is driven by increasingly stringent government regulations to meet fuel efficiency standards and reduce carbon emissions.

In the U.S., for example, the Corporate Average Fuel Efficiency (CAFE) standards mandate that carmarkers’ passenger vehicle fleets average 54.5 miles/gal by 2025, and according to IHS Markit estimates, fuel economy must be improved by approximately 50% across the passenger vehicle fleet. This is resulting in the increasing use by automakers of newer-generations plastics and plastics composites.

For the most part, mainstream automakers are initially employing traditional metalworking approaches to weight reduction, as these offer a cost-effective application of known competencies, secure supply chains and more importantly, existing capital equipment. However, automakers are increasingly employing more novel approaches, such as adopting plastics and next-generation composites into automotive design, particularly for larger vehicle applications, according to IHS Markit.

Said Casey Selecman, senior manager of automotive advisory services at IHS Markit, “While metal and metal alloys are still critical to automotive design, automakers are finding innovative ways to leverage plastics and composites into their designs to help reduce vehicle weight and improve efficiency. As efficiency and carbon reduction regulations increase globally, we at IHS Markit expect the use of plastics will only increase as the materials improve and production costs are reduced.” He also noted that the use of advanced plastics and composites also give automotive designers a freedom of expression that would be impossible with conventional metals, such as steel or aluminum. “Beyond the practical advantages of using plastics and composites, these materials can enhance the design and aesthetic appeal of cars, and while performance, structural strength and safety are key purchase considerations, buyers also look for designs that appeal to the head and the heart.”

The company’s automotive researchers note that cars represent a fast-growing market for the chemicals industry, with global car production expected to rise in the coming years to more than 110 million units in 2025, up from an estimated 88.7 million in 2015. Much of the growth is expected to come from the fast-expanding Chinese market.

Uses for advanced plastics and plastic composites now range from electronic components, through to body panels, lift-gates, seatbacks, center consoles, interior trim, and underhood applications. These materials are often compounded with fiberglass and additives to boost mechanical properties and stability. According to IHS Markit the use of carbon fibers and polymer matrix composites are enabling car-body weight-reductions of an estimated 25% to 70%, and company chemical analysts expect the market for carbon fiber in automotive manufacturing to nearly double in the next few years.

Said Selecman, “There is still huge opportunity for automotive light-weighting on the horizon—literally tons of weight yet to be removed from vehicle designs using material substitutions such as innovative plastics composites and carbon fiber technologies. Closures, which are doors, lift-gates and hoods, are the easiest options to significantly reduce vehicle weight, and at IHS Markit, we see significant opportunities for those as well as non-critical structures such as seats, instrument panels, and under the hood for engine cradles, pans, covers, and so on.”

The company expects usage of carbon fiber in automotive manufacturing to nearly double from 2015 to 2020, according to Michael Malveda, lead author of the newly published report from IHS Markit, IHS Chemical Carbon Fibers, Chemical Economics Handbook. “We expect the use of carbon fiber composites in mainstream cars and trucks to increase, but improvements will need to be made in carbon fiber processing technology to make it more cost-effective for mass-produced automobiles.”

Selecman, along with other IHS analysts and industry leaders and plastics manufactures, including Brian Baleno, global automotive business development manager for Solvay Specialty Chemicals, will participate in this key panel discussion.

Related Content

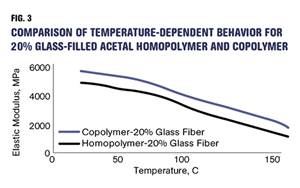

How Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreLanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

Read MorePrices of Volume Resins Drop

Price relief is expected to continue through the fourth quarter for nine major commodity and engineering resins, driven by widespread supply/demand imbalances.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More