Permanent Labeling Technology for LSE Polyolefin Parts Further Expanded

MIGs’ innovative VersaFlex Labeling System can be used for decorating blow molded, injection molded, thermoformed and rotationally molded polyolefin products,

Mold In Graphic Systems (MIGS; Clarksdale, Ariz.) made its mark over three decades ago in permanent labeling of rotationally molded polyolefins and has made significant strides in the injection molding arena since 2012. Now, MIGS has come up with an innovation that promises to further, if not revolutionize, the technology of permanent labeling for a broad range of low-surface-energy (LSE) polyolefin blow molded, injection molded, thermoformed and rotationally molded parts.

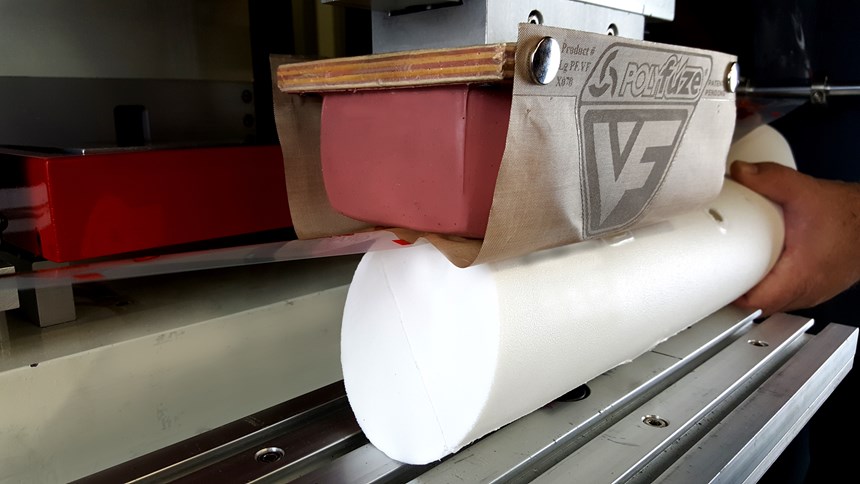

CEO Marty Mares and Senior Director Jason Brownell explained to us recently that the new VersaFlex Labeling System has two components: The company’s specialty Polyfuze pigmented polymer graphics and a new customized flexible heating die assembly, with a proprietary heat-retaining component that applies permanent graphics.

As reported previously, the Polyfuze graphics decoration process for injection molded plastics simply requires the use of a standard hot-stamp machine and an 80-durometer silicon die to fuse the graphic permanently into the part to become one piece. No adhesives, inks, clear coats nor surface pre-treatments are required with this unique secondary process. And while the graphics may look like a heat transfer or hot stamp foil, the polymer-based material that comprise Polyfuze graphics have been shown to outperform these traditional alternatives.

The new proprietary heating element utilizes a 40-durometer flexible silicone pad print pad on “modified pad printing machines” which essentially picks up heat instead of ink—explains Brownell. Essentially, VersaFlex requires a new generation of special machines—and MIGS is working with a variety of manufacturers that would adapt this technology.

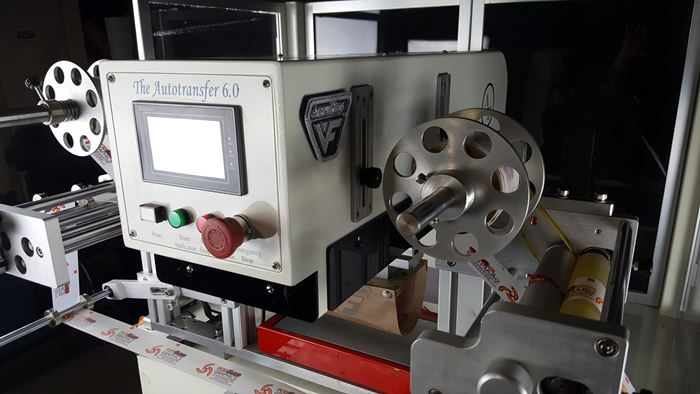

The company has been working with a modified Autotran pad printer to prove its technology, which has the capability of permanently marking hollow parts with a small opening not allowing for support on the inside wall. And Brownell notes that whereas application of hot stamp foils or heat transfers require pressure of 400-500 psi, VersaFlex only requires 25 psi. Says Brownell, “You can decorate larger areas with smaller machines. You’re basically eliminating the air and allowing the heat in. The Autotran machine we’re using has a hot plate that we run at 450 F.”

Mares notes that Polyfuze heat-melded durability exceed IMLs, stickers, foils and more, adding that this is the only “pure fusion” technology for LSE polyolefin products globally, to his knowledge. “The VersaFlex Labeling System is designed for flat, curved or multi-shaped LSE polyolefin parts. It saves time, money and scrap—using one label once…and, not having to replace it due to failure means protection against litigation.”

Related Content

-

X2F and Covestro Collaborate on Innovative In-Mold Electronics for Automotive Lighting

Thermally conductive PC heat-sinks produced with X2F controlled viscosity molding.

-

Portable Alligator Shear for Size Reduction of Oversized Plastic Scrap

BCA Industries’ PGS100 hydraulic shear can quickly cut oversized plastic items into smaller pieces for easier shredding.

-

Metaspectral to Advance Vision Technology for Recycling

Company received further funding from British Columbia’s CleanBC Plastics Action Fund