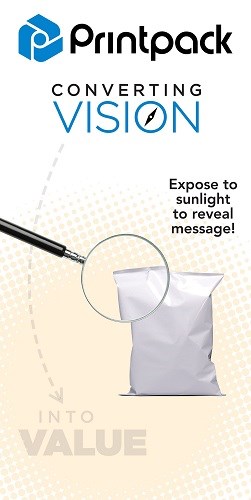

Photochromic Ink for Flex Packaging Helps Brand

Printpack's process allows for photochromic ink to be hidden and remain invisible until exposed to sunlight.

At last week’s Pack Expo in Las Vegas, a new way for brands to interact and engage with consumers was launched by Printpack, Atlanta, Ga. The company has developed a proprietary process that allows for photochromic ink to be hidden within standard graphics and remain invisible until exposed to sunlight.

Printpack showed a sample application of its technology at the show, whereby attendees could see the package transform firsthand. According to the company, this process represent the first time photochromic ink has been applied to a flexible film, giving brand owners in any market that utilizes flexible packaging new options for interacting with their customer base.

The application of photochromic ink for the flexible packaging industry for years had been a challenge, particularly in high-speed production environments—in turn limiting options for brand owners looking to differentiate their product. Printpack’s R&D team designed the innovative process to apply the ink while still upholding the integrity of the packaging design and graphics to the highest standards, according to the company.

Printpack says interactive packaging is proven to capture consumer attention and encourages engagement with the brand in a meaningful way. Notes director of technology Mark Brogan, “This type of packaging application can truly set a brand apart by adding depth to the consumer experience. It can make all the difference when it comes to purchasing decisions.”

Related Content

-

Ultrasonic Inserts and Heat Staking Kits for Thermoplastics

Made from brass with inch or metric threads, the E-Z Sonic inserts in E-Z Lok’s threaded insert assortment kits can be installed via ultrasonic horn or heat driver.

-

‘Contactless’ Accumulator Is Gentle to Superthin PET Bottles

Sidel’s Gebo AQFlex protects ultralight PET water bottles from dents at Suntory Japan.

-

A Guide to Ultrasonic Welding Controls

Ultrasonic welding today is a sophisticated process that offers numerous features for precise control. Choosing from among all these options can be daunting; but this guide will help you make sense of your control features so you can approach your next welding project with the confidence of getting good results.