Plastic Food Packaging and Sustainability During COVID-19

Bob Maughon, executive vice president, technology & innovation for SABIC, discusses the role of plastic food packaging and sustainability in light of today’s public health climate.

Plastic packaging usage is increasing but end-of-life issues remain.

2019 was the year the focus really centered on a circular economy for plastics. It was the theme of many booths during the K 2019 show, which saw lots of new technology and innovations launched around sustainability.

We all expected 2020 as the year poised for the circular economy to take off. And then COVID-19 happened and in an instant, the world seemed to stop.

However, several unexpected developments have happened. There is a renewed interest in food packaging and consumer safety. Many consumers are really seeing the benefits of plastic packaging in this area. But there’s still the end-of-life issue to consider.

Bob Maughon, executive vice president, sustainability, technology & innovation and CTO and CSO for SABIC, believes innovative packaging solutions allow for protection of both the public and the environment.

So it’s not one or the other—we can still have efficient single-use plastic packaging and also ensure that it falls in line with the circular economy.

I recently talked with Maughon about his thoughts on this, the impact of COVID-19 and what the future of sustainability looks like.

The Company’s Response to COVID-19

Maughon said SABIC is focused on protecting employees and making sure the supply chain is still functioning in order to meet customer needs. There are new procedures in place that ensure employee safety and some positions are being performed at home for the time being.

The company recently announced that it is donating $1.5 million in monetary and in-kind product donations in the Americas region to assist those most impacted during the COVID-19 pandemic. This includes providing SABIC-produced plastics products to be used in the manufacture and donation of vital medical equipment.

SABIC, whose Americas head office is based in Houston, will donate approximately $1 million to food banks and community-based agencies, such as the United Way, in the communities where it operates to assist those struggling in the wake of the pandemic. SABIC is also donating approximately $500,000 of its products, made at its facilities in the U.S., Canada, Mexico, Argentina and Brazil, in the manufacture and shipment of personal protection equipment for healthcare workers and needed medical equipment such as ventilators, patient monitoring devices, respiratory therapy machines and diagnostic equipment.

“Times like this, you see the team bringing in new ideas and coming up with solutions, and you get to see the true power of an organization,” Maughon said.

Plastic Packaging for Safety

Maughon said that plastic packaging materials are an important factor to reduce food waste and in protecting consumers.

“There have been huge issues in the food supply chain and the normal supply routes are not functioning, so packaging is critical in improving shelf life and in getting food directed to the right place while limiting waste,” he said. “The consumers want the products protected and for them to be safe.”

That being said, Maughon said the end-of-life issue is still a critical challenge right now.

“In my view, this COVID-19 crisis has reaffirmed how important these materials are to protecting consumers and products, but at the same time, this doesn’t reduce the need to address the plastics end-of-life challenge.”

Sustainability Still a Focus

While there is a significant demand for plastics in food packaging, personal and home care packaging, and personal hygiene and medical products, there’s still a lot of work required on the recovery side.

At K, SABIC introduced its TRUCIRCLE initiative and solutions, which included SABIC’s flagship certified circular polymers from the chemical recycling of mixed plastic waste, certified renewable polymers, its new polycarbonate (PC) based on certified renewable feedstock, and mechanical recycled polymers.

Additionally, SABIC highlighted its Design for Recyclability for the creation of packaging products, which from their inception, aim to minimize waste and help to enable 100% recyclability. SABIC also introduced its new LLDPE polymer, which is designed for creating biaxially oriented polyethylene (BOPE) films.

“With TRUCIRCLE circular products and the design for recyclability angle, we see this as critical and that we have a role to address the end-of-life,” Maughon said. “While there is maybe a shift in focus around the COVID-19 front for government and regulatory bodies, the (waste) issue has not gone away. We’re still committed and still getting the same draw from the value chain. The pressure of the circular economy hasn’t been diminished.”

Maughon said sustainability investments can take months and years to come to fruition but that the brands are still concerned over the issue and consumers are as well.

“We have to protect public health but we can’t ignore the waste issue,” he said. “We believe in the right products and solutions. Plastics application in food packaging, personal and home care packaging, and personal hygiene and medical products is a necessity but, at same time, we need to have sustainable solutions that address the end-of-life challenge. You can’t solve one problem by creating another.”

Related Content

Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

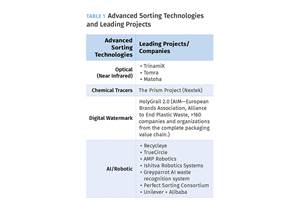

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreRead Next

‘Circular Economy’ Will Be Unifying Theme at K 2019 Show

Even injection machine suppliers like Engel will talk about ways their technology can support recycling.

Read MoreK 2019 Video: Innovations in Recycling Machinery and Materials

From the K 2019 show floor, hear from Bengt Rimark of Rapid Granulator and Bob Maughan of SABIC as they talk about new recycling technology and developments.

Read MoreWhat Is the Circular Economy?

In this video from K 2019, hear NOVA Chemicals, TOMRA, Covestro, Rapid Granulator and SABIC each discuss plastics’ role in the circular economy.

Read More

.png;maxWidth=300;quality=90)