Post-Consumer PET Bottles Turned to New ‘True’ Black Jeans

Unifil’s Repreve recycled fiber used by Cone Denim in a new line of black jeans.

A three-way collaboration has resulted in the launch of Future BLACK+, a new line of black jeans, each pair of which contains up to 17 recycled PET bottles—said to be the most post-consumer recycled content the industry has seen in denim. Superior softness, color retention and stretch are also claimed. I, for one, would love to try them—both for the sustainability aspect and the color retention of a ‘true black’ jean!

The three players include Cone Denim, a leading supplier of denim fabrics to top denim apparel brands since 1891 and Unifil Inc., whose proprietary technologies of synthetic and recycled performance fibers include the renowned Repreve fiber brand resourced from post-consumer PET bottles—both of Greensboro, N.C. The third pary is The Lenzing Group of Austria, which supplies the global textile and nonwovens industry with high-quality, botanic cellulose fibers.

Lenzing’s portfolio ranges from dissolving wood pulp to standard and specialty cellulose fibers. With 79 years of experience in fiber production, the company is reportedly the only manufacturer globally capable of producing significant volumes of all three cellulose fiber generations—from the classic Lenzing Viscose branded fibers to the Lenzing Modal branded fibers—which are used in the new Cone Denim jeans product line—and the Tencel branded lyocell fibers. Just last year, Lenzing introduced the Refibra branded lyocell fibers—a product innovation based on recycled cotton scraps.

Cone Denim’s Future BLACK+ denim is said to achieve its durable color by utilizing dope dyeing, an energy-saving and environmentally friendly dyeing technique that introduces the pigment during the production process. Adding the colorant during manufacturing allows the entire body of the fiber to be colored instead of only the surface and eliminates the need for a dye bath later in the process. Wash tests have shown that denim made from Future BLACK+ showed no sign of color loss even after more than 20 washes, producing a denim that’s built to last.

Says Tricia Carey, Lenzing’s director of global business development for denim, “Lenzing has always been committed to sustainability and making our manufacturing process as eco-friendly as possible…by partnering with Cone Denim and Unfil, we were able to work with like-minded companies to create an advanced product that saves resources throughout the manufacturing process.”

In addition to Unifil’s Repreve, a leading brand of PET fibers made from recycled plastic bottles, Lenzing’s Modal BLACK has around 50-60% lower environmental impact than conventional dyed fabric. The Lenzing manufacturing process reportedly requires less chemical and energy input during manufacturing, and uses 64% less water during the dye process. Together, these earth-friendly fibers create a high-performing, highly-sustainable denim.

Says Jay Hertwig, Unifil’s v.p. of global brand sales and premium value-added sales, “By combining Lenzing Modal fiber with Repreve, we are able to satisfy some of the biggest consumer demands for the marketplace. Unifil is proud to work with both The Lenzing Group and Cone Denim to create a high-quality product that helps decrease our industry’s environmental footprint.”

The new line was launched on October 25-26, 2017 at Kingpins Amsterdam, and will also be showing at Kingpins New York, Nov. 29-30, as part of the Cone Denim True Tone collection.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

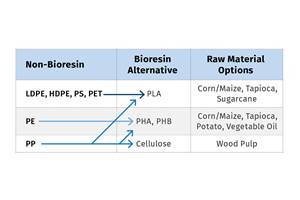

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

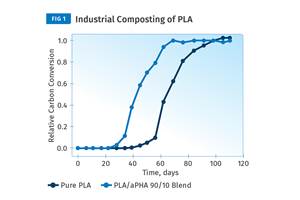

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More