Researchers Discover Plastic-Eating Enzyme

The team’s goal is to use their findings to continue to improve the new enzymes to break down these plastics, but in a fraction of the time.

New research claims that an enzyme can break down ubiquitous plastic bottles made of PET in what could eventually revolutionize recycling. This breakthrough in enzyme research was led by the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) and the United Kingdom’s University of Portsmouth.

While working to solve the crystal structure of PETase—a recently discovered enzyme that digests PET—the team inadvertently engineered an enzyme to be even better at degrading the man-made substance. Although the improvement is modest, this unanticipated discovery suggests that there is much more room to further improve these enzymes, moving scientists closer to solving the problem of an ever-growing amount of discarded plastics, the researchers stated.

The paper, “Characterization and engineering of a plastic-degrading aromatic polyesterase,” was published in the Proceedings of the National Academy of Sciences (PNAS). The lead authors from the research team—NREL’s Gregg Beckham, University of Portsmouth’s John McGeehan, and Lee Woodcock from the University of South Florida—were attempting to understand how PETase evolved from likely working on natural substances to digesting synthetic materials when the discovery was made.

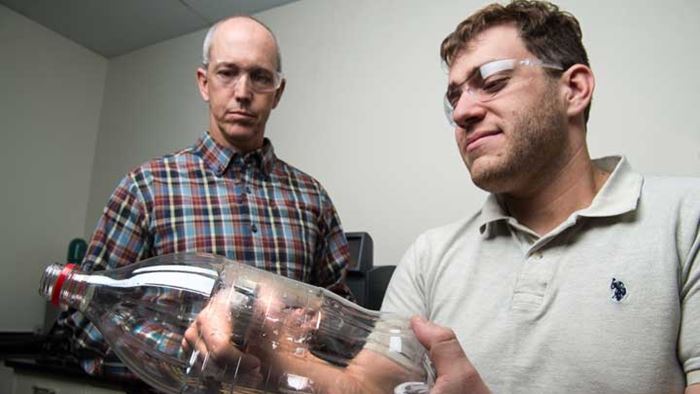

To begin experiments, the research team wanted to find out exactly how effective PETase was at digesting PET. NREL Senior Scientist Bryon Donohoe and postdoctoral researcher Nic Rorrer tested PETase by taking samples of PET from the soda bottles in Beckham’s office and ran an experiment with PETase. “After just 96 hours you can see clearly via electron microscopy that the PETase is degrading PET,” Donohoe says. “And this test is using real examples of what is found in the oceans and landfills.”

“We originally set out to determine how this enzyme evolved from breaking down cutin—the waxy substance on the surface of plants—with cutinase, to degrading synthetic PET with PETase,” said Beckham. “We hoped to determine its structure to aid in protein engineering, but we ended up going a step further and accidentally engineered an enzyme with improved performance at breaking down these plastics. What we’ve learned is that PETase is not yet fully optimized to degrade PET—and now that we’ve shown this, it’s time to apply the tools of protein engineering and evolution to continue to improve it.”

NREL and the University of Portsmouth collaborated closely with a multidisciplinary research team at the Diamond Light Source in the UK, a large synchrotron that uses intense beams of X-rays 10 billion times brighter than the sun to act as a microscope powerful enough to see individual atoms. Using their beamline I23, an ultra-high-resolution 3D model of the PETase enzyme was generated in a reported exquisite detail.

With help from the computational modeling scientists at the University of South Florida and the University of Campinas in Brazil, the team discovered that PETase looks very similar to a cutinase, but it has some unusual surface features and a much more open active site. These differences indicated that PETase must have evolved in a PET-containing environment to enable the enzyme to degrade PET. To test that hypothesis, the researchers mutated the PETase active site to make it more like a cutinase.

And this is where the unexpected happened. “Surprisingly, we found that the PETase mutant outperforms the wild-type PETase in degrading PET,” said Rorrer. “Understanding how PET binds in the PETase catalytic site using computational tools helped illuminate the reasons for this improved performance. Given these results, it’s clear that significant potential remains for improving its activity further.”

Another significant aspect of the research: the discovery that PETase can also degrade polyethylene furandicarboxylate, or PEF, a bio-based substitute for PET plastics. The enhanced oxygen barrier properties of PEF could lead to its widespread use in bottles, the researchers stated.

The team’s goal is to use their findings to continue to improve the new enzymes to break down these plastics, but in a fraction of the time.

Related Content

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More