"Revolutionary" Device Makes Purging Safer, Simpler

What is said to be a “revolutionary” device designed to capture molten plastic purges and create a safer environment for personnel and equipment in plastic processing operations is being introduced at NPE2015 by the Dyna-Purge div. of Shuman Plastics. Lava-Shield is the result of a two-year development project and hundreds of rigorous field trials.

What is said to be a “revolutionary” device designed to capture molten plastic purges and create a safer environment for personnel and equipment in plastic processing operations is being introduced at NPE2015 by the Dyna-Purge div. of Shuman Plastics.

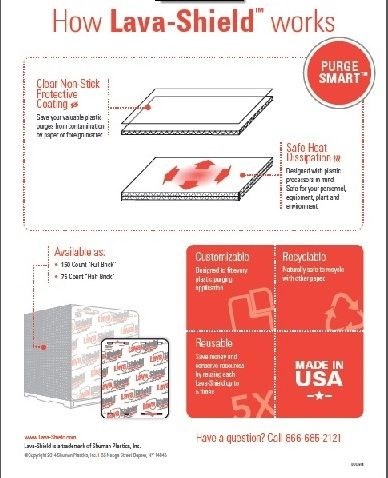

Lava-Shield is the result of a two-year development project and hundreds of rigorous field trials. This protective purge guard is said to be easy to use with a variety of processing equipment including injection molding, extrusion, compounding, blow molding and film of virgin and recycled materials. Field studies found that most purges were shot onto cardboard, or even worse, grabbed by hand with a hot glove or rag. Such operations always result in waste because the purge gets contaminated and has to be disposed of—aside from the injury potential to personnel.

Designed with a unique combination of specialty papers, Lava-Shield absorbs and then dissipates heat quickly and will not hold or transfer heat. When the purge cools, the special non-stick surface releases the purge, free from contamination, The purges can then be recycled or sold for values. This protective purge guard is reusable up to five times, made in the U.S. with up to 30% recycled content and, can be recycled along with other plant and office waste paper.

Says company president Ken Shuman, “Plastics purges are extremely hot and our clients challenged us to create a device that could take the heat in capturing the purges while also protecting employees and equipment. They wanted something that is safe to use, easy to customize, with quick release properties to keep purges clean…and it should be reusable and recyclable. We responded and are proud to introduce Lava-Shield, designed with plastics processors in mind to help them purge smart.”

Lava-Shield is available in 150 count “full-brick” quantities, or 75 count “half-brick” quantities. A free sample is available for qualified applications.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

-

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.

-

Commodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)