What is the true cost of a bimetallic barrel for a processor? The price paid for this component is just the beginning. Added to that is the cost of ownership, or lifetime cost. The working life of a barrel can be disastrously short, depending on how it was manufactured, how it was handled before it reaches the processor, and how it is used by the plastics processor. Seemingly minor imperfections in a new barrel can cause premature wear to barrel and screw, adversely affect end-product quality, increase reject rates, or force production downtime. As a result of problems like these, a barrel purchased based only on price can ultimately cost more than higher-priced alternatives.

What follows is a look at factors that can affect the true cost of a barrel, starting with its basic composition and following with a consideration of factors that might otherwise be overlooked, like shipping and handling.

Inlay Composition

In the Americas and most of Europe, barrels are typically bimetallic—that is, the base metal, or backing, has an internal lining or inlay of an alloy formulated to resist wear or corrosion. In Asia, one-piece barrels are still common, but bimetallic barrels are increasingly produced for local use and export.

The process of producing the inlay for a bimetallic barrel is called centrifugal casting. It involves using heat to apply an alloy powder to the inside of a pre-bored barrel, then spinning the barrel to force the molten alloy against the inside wall. The conventional method for applying heat is to use a gas-fired furnace, though Nordson now employs induction furnaces which take less time to apply the linings, provide more consistent barrel quality, and allow for very large barrels as well as standard sizes.

Short of employing special metallurgical techniques, it is a challenge for most processors to prove out a barrel inlay. Nevertheless, the composition, uniform thickness, and the lack of porosity of the inlay are critical determinants of the quality and thus the working life of the barrel. The quality is determined by the reliability and repeatability of the centrifugal casting process. The composition—of both the backing and the inlay—should be documented with traceable metallurgical data from the supplier.

With the increasing use of abrasive fillers, particularly glass-fiber reinforcements, inlay materials containing metallic carbides have been developed. The carbides (based on tungsten, titanium, or tantalum) are suspended in a matrix of nickel, cobalt, chromium, boron, or some combination of these corrosion-resistant materials. The resulting inlay is more corrosion-resistant than general-purpose barrels. (Selection of a proper screw material is critical; some screw hard-surfacing materials used in combination with carbide-lined barrels can lead to catastrophic wear.)

The ideal thickness of a barrel inlay is 1.6 mm or 0.063 in.

For use with corrosive materials such as fluorocarbons, an alternative inlay provides chemical resistance with some sacrifice of wear resistance. The typical composition is nickel, chromium, boron, and cobalt. The inlay should be used with a nickel-based backing or a trimetallic combination of nickel-based and carbon-based backing steel.

The ideal thickness of an inlay is 1.6 mm or 0.063 in. As thickness increases beyond this point, it is a case of diminishing returns.

Backing Composition

The control and repeatability of the centrifugal casting process affects not only the quality of the inlay but also the performance of the backing material, which anneals during the high temperature spinning oven, followed by slow cooling. The quality of the backing is especially important in barrels for injection molding. Pressures at the very end of the injection stroke typically reach 20,000 psi. (138 MPa) and can go even higher, putting the entire plasticating unit in tension. A poorly manufactured barrel can break and cause damage to the screw, tip, end cap and feed housing.

To cope with this pressure, barrel suppliers use a high-pressure sleeve made of a strong, heat-treated alloy steel; this is shrunk over the centrifugally cast barrel. Alternatively, special alloy steels can be used that achieve 50% higher pressure-carrying capability, eliminating the sleeve in favor of single-piece construction.

A poorly manufactured barrel can break and cause damage to the screw, tip, end cap and feed housing.

Shipping and Handling

Even a well-made barrel can arrive with imperfections or damage incurred during shipping. The probability of damage increases with the amount of handling that the barrel undergoes between the original manufacturer and the extrusion or molding shop. These intervening “handlers” can include truckers, shippers, resellers, and warehouses.

Ocean shipping also presents the risk of constant vibration as the barrel sits on the deck of a ship. This is a problem because a barrel is a piece of steel that has a lot of built-in stress. Constant vibration releases that stress, affecting the dimensions and straightness of the barrel. Also, ocean transport is a special challenge because of the corrosive effect of saltwater environments. The barrel should be well protected with rust inhibitor and wrapped in film or paper to prevent corrosion. Extensive rusting will make the barrel unusable.

Poor or inappropriate packaging is another risk. Unless correctly braced inside a substantial shipping package, the barrel can move around inside during transport and handling, causing damage. Even a small barrel is heavy enough to destroy a poorly made shipping container and can come out during handling. Abrasion on a concrete floor, scraping by a forklift, cantilevering at the lift point when raised by a chain hoist—these are examples of damage that can occur.

Straightness and Concentricity

Fixing a new barrel that deviates from straightness is very difficult to do after the fact. Shop-floor workarounds can do more harm than good. Yet a significant deviation can make it difficult to mount the barrel onto the machine, let alone insert the screw. Even a seemingly minuscule deviation can adversely affect performance and end-product quality. Possibly it could lead to catastrophic failure.

Consider the critical clearance between screw and barrel. In an 80 mm (3.15 in.) barrel, the clearance needs to be held to a range of 0.076 to 0.102 mm (0.003 to 0.004 in.) on either side of the screw. If this clearance is out of tolerance, the rubbing between screw and barrel not only causes wear to both components but also generates metal particles that contaminate the end-product—a grievous problem in medical devices, cable coatings, and other high-specification applications.

Fixing a new barrel that deviates from straightness is very difficult to do after the fact.

The heat generated by this rubbing also affects the polymer, degrading it and causing galling that, at its worst, can cause the plasticating system to seize up.

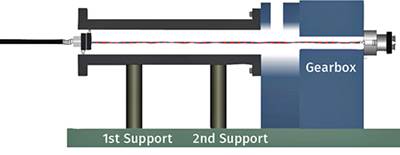

The longer the barrel, the broader the straightness tolerance range. Because the I.D. and O.D. of a barrel are not usually concentric in the center, straightness is difficult to determine in the extrusion or molding shop without special equipment. Laser systems provide the greatest accuracy, but in most cases the processor will need to resort to a qualified outside service.

Surface Finish and Workmanship

A barrel should be smoothly finished and polished, including the ID, external surfaces, and fastening sites. Aesthetics is not the reason. A smooth, uniform surface is essential for effective performance.

Contact with heater bands, for example, must be close and uniform. A wavy barrel surface caused by hand polishing to remove rust or defects will prevent efficient heat transfer.

Surface uniformity is also essential for metal-to-metal seals, as in the case of the flange connecting the barrel to the end cap or nozzle adapter in injection molding, or the flanges connecting the barrel to the feed throat and to the die adapter in extrusion. Uneven surfaces result in polymer leakage and could lead to metal erosion. Leakage can also occur with poor surface quality in counterbores. Repairing these problems will require disassembly to re-machine or may require sending the barrel back to the supplier to be re-machined.

Also requiring re-machining are poorly drilled holes, such as those for mounting components or seating thermocouples. Holes may not be drilled deep enough or may have burrs.

ABOUT THE AUTHOR: Randy Elliott is engineering manager for Nordson Corp.’s Xaloy products. After starting out in industry as a CNC programmer, in 1985 he joined Xaloy, which was acquired by Nordson in 2012. He served in engineering and inside sales positions before going to Thailand in 2001 to work on the startup of the new Xaloy facility there. Randy spent two years in Thailand before returning to the USA and assuming his current role as head of product engineering. Contact: (540) 994-2238; randy.elliott@nordsonxaloy.com; nordsonxaloy.com

Related Content

Cooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreRead Next

Barrel Repair: When Does It Make Sense?

Repairing a barrel can save you time and money vs. buying a brand-new one. But it’s not an easy fix and not even always possible.

Read MoreHow to Spec’ Screws & Barrels For Running Corrosive Materials

Here’s a guide to specifying screws and barrels that will last under conditions that will chew up standard equipment.

Read MoreKeep Extruder Barrels Aligned…And Production on Target

A misaligned barrel causes a lot of trouble. Laser alignment is being used now to keep things on the straight and narrow.

Read More

.png;maxWidth=300;quality=90)