Solvay's Advanced Thermoplastics In Polimotor 2 Car Engine

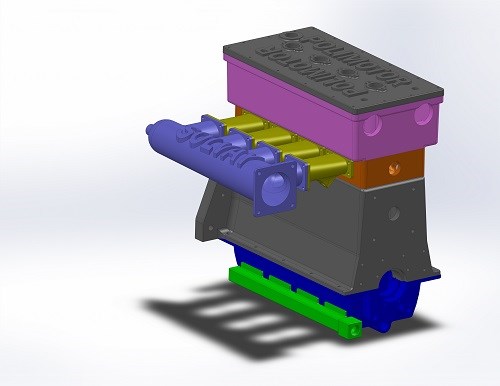

Up to ten parts of the Polimotor 2 engine will be made of at least seven of Solvay's advanced engineering polymers.

While it’s taken 25 years to remerge, work on an all-plastic automotive engine is well underway. In fact, the Polimotor 2 engine will make its debut in a race car next year and several advanced thermoplastics from Solvay Specialty Polymers are an integral part of the design. The four-cylinder, double-overhead CAM Polimotor 2 engine will be installed in a Norma M-20 concept car that will compete at the 2016 racing of Lime Rock Park, Conn.

First, a bit of history. Some of you might remember hearing about Polimotor 1 back in the late 80s--a joint project of New Jersey-based Polimotor Research and Ford Motor. Although that engine was never installed, the ambitious project resulted in an engine based on Ford’s 2.3-liter Pinto engine and weighed 153 lbs vs. 415 lbs for its then cast iron counterpart. It comprised metal cylinder sleeves, metal combustion chamber tops, metal piston crowns, bearings, valves and seats, and a stock 2.3L Pinto crankshaft. Nearly everything else—including the block, rods and piston skirts—were made of Torlon PAI (polyamide-imide) then made by Amoco Chemical and now one of Solvay’s key advanced polymers.

Fast forward to Polimotor 2: Solvay is aiming for an engine that will weigh 138 to 148 lbs, or about 90 lbs less that today’s standard production engine. Of course, the company is hoping that this development will translate to further innovation for future commercial cars. In their press release, Solvay noted that at least ten engine components—including the intake manifold (plenum), air duct (runner), cam sprockets, throttle body, water pump, oil pump, and fuel rail—will be made of at least seven of its materials.

In my recent inquiry, Solvay officials offered some further details starting with this: “Polimotor 2 is the evolution of Polimotor I where new polymers and technologies will be introduced that were not commercially viable in the 1980s. Additionally, Polimotor 2 uses carbon-fiber reinforcement while Polimotor 1 used fiberglass reinforcement. Polimotor 2 takes several cues from Polimotor 1 including the return of the four cast combustion chambers and the four machined cylinder bores which are mechanically incorporated into the engine.”

My sources also noted that Solvay’s global leadership in automotive has had a long history of supplying high-performance polymers which improve powertrain efficiency, enable electrification, and reduce vehicle emissions. They list the following polymers offered for this project, Torlon PAI, Amodel PPA, Ryton PPS, Radel PPSU, AvaSpire PAEK, KetaSpire PEEK, Tehnoflon FKM, Technyl PA66, and additive manufacturing materials Sinterline and Technyl Powders. They say they will provide more detailed information on the specific components as they are designed and a final material selection has been made. Some new materials and technologies will also be highlighted by the company as the Polimotor 2 engine design progresses.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastics Technology’s Plaspec Global materials database.

Related Content

-

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you'll see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

Design Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

.png;maxWidth=300;quality=90)