Variotherm Molding Can Double Flow Length, Cut Cavity Pressure By 70%

RocTool’s year-old HD Plastics Materials Database further expanded.

RocTool’s year-old HD Plastics Materials Database further expanded.

At PT’s Molding Conference 2016, held in New Orleans, we were told of the new concept of “High Definition Plastics” by Steve Verschaeve, v.p. of North American business development for RocTool Inc., Charlotte, N.C.

The HD Plastics Material Database was expressly developed to educate the market to the benefits of Heat/Cool (or “Variotherm”) injection molding using RocTool’s electromagnetic induction heating coils and its new high-performance cooling units.

Now, the company has completed a study to identify a range of resin materials that can successfully apply RocTool’s molding technologies to produce high-quality parts with high flow and reduced cavity pressure. This study is part of RocTool’s ongoing effort to further develop its HD Plastics Material Database, which is designed to help designers and processors achieve exceptional part quality and increased performance without secondary operations such as painting or decorative films. The Database in available to RocTool process users.

To demonstrate the advantages of RocTool’s technologies including improved flow, reduced cavity pressure, high-surface replication of the mold, and significant gloss improvement, the company worked in tandem with RJG, Inc., Traverse City, Mich. Among the main challenges in the industry is reducing overall part thickness. The flow increase with RocTool induction heating technology delivers design opportunities and pushes the limits in creating thin-wall applications.

RocTool developed a specific spiral mold to calculate the flow length while pressure sensors were implemented by RJG to assess the capability of RocTool’s technology to improve mold filling and reduce cavity pressure. The spiral tool was developed with variable thickness (from 0.5 mm to 1.5 mm) allowing a complete material characterization. RJG’s process monitoring eDart System collected the data from the sensors, which were installed behind the ejector pin and located close to the gate and at the end of the fill.

According to RocTool CEO Mathieu Boulanger, the company is evaluating a range of resins from various material suppliers. The company is now capable of demonstrating the additional benefits of its technology beyond just a cosmetic advantage. RocTool can reportedly provide true comparison data for parts produced with its technologies versus those made via conventional injection molding.

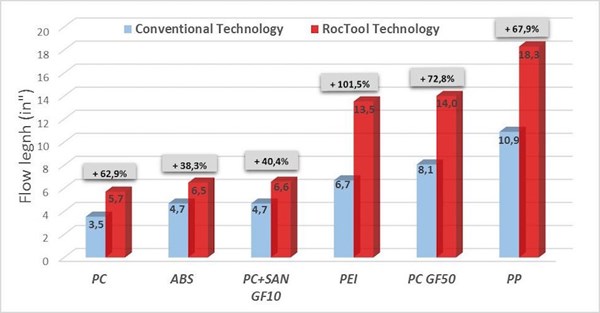

This first study includes six resins covering commodity, premium, and performance categories. Depending on the material, the evaluation revealed that RocTool’s molding technologies can double the flow length and reduce the cavity pressure by as much as 72.6% compared to conventional injection molding methods for thin-wall applications.

Verschaeve will once again present at Molding 2017 this April in Charlotte, and at the end of the conference, attendees can register for a free tour of RocTool’s Charlotte technology center.

Related Content

-

Captive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

-

Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

-

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.