Sustainability: What Does It Actually Mean?

Is your business adapting—or ready to adapt—to growing calls for sustainability? It would help to know what sustainability really means to those who are pushing for it as a key social, governmental and industrial goal.

Sustainability is about much more than the manufactured product, and it’s about more than the environment—recycling, waste reduction, energy efficiency, etc. The good news is that plastics processors are concerned with all of what Sustainability entails—even if they don’t think of it that way. (Photo: Graham Packaging)

Last week, I wrote a brief “book review” of a highly useful new publication from consulting engineer Dr. Robin Kent, whose 18 articles on energy management in plastics processing (adapted from his book of that title) graced our pages from 2009 to 2013. His brand-new guide to Sustainability Management in Plastics Processing (434 pp.) has got me thinking some more about what does Sustainability really mean, and how does it relate to plastics product manufacturing. I think relatively few people understand just how much is packed into those five syllables. Lift the lid a little, and quite a bunch of concepts and propositions pop out, including stuff that people dedicated to the day-to-day challenges of manufacturing might not have anticipated.

Dr. Kent quite sensibly starts his book with the principle that you can’t evaluate or organize your plastics operations for sustainability unless you know what the term actually means as it’s being used today. (You won’t even find the term in that decades-old dictionary on your bookshelf.)

Addressing the question in Chapter 1 of “What is sustainability?” Dr. Kent offers two definitions. One comes from the UN World Commission on Environment and Development in 1987 (the so-called Bruntland definition):

“Sustainable development seeks to meet the needs and aspirations of the present without compromising the ability to meet those of the future. Far from requiring the cessation of economic growth, it recognizes that the issues of poverty and underdevelopment cannot be solved unless we have a new era of growth in which developing countries play a large role and reap large benefits.”

Dr. Kent notes that citations of this definition often don’t go beyond the first sentence and totally ignore the key phrase, “Far from requiring the cessation of economic growth ...” That connection, Kent says, is “missing in some of the ‘hair shirt’ approaches to sustainability promoted by some environmentalists.” My mind jumps to recent calls for governments to ban any number of “single-use” plastic products or to cap any further expansion of capacity for producing virgin plastics. I’m not sure what the foregoing has to do with solving “poverty and underdevelopment” in the last part of the UN definition, other than the proposition that economic growth in the developed world is essential to growth in the underdeveloped world. (Sorry, is that “trickle-down” economics?)

The second definition cited by Dr. Kent comes from the U.S. Dept. of Commerce’s Sustainable Manufacturing Initiative, which defined sustainable manufacturing as, “The creation of manufactured products that use processes that minimize negative environmental impacts; conserve energy and natural resources; are safe for employees, communities and consumers; and are economically sound.”

The U.S. EPA posts a similar definition on its website: “Sustainable manufacturing is the creation of manufactured products through economically sound processes that minimize negative environmental impacts while conserving energy and natural resources. Sustainable manufacturing also enhances employee, community and product safety.”

I like the reference to “economically sound processes,” which manufacturers tend to pursue without any encouragement from governmental agencies. But, as Dr. Kent points out, these definitions make clear that sustainability is about more than the manufactured product—“The social issues are much broader than the simple product issues,” he states in his book. What’s more, sustainability is even about more than the environment—more than recycling, more than landfill waste reduction, more than energy efficiency. Yes, it is those things, but also much more.

Sustainability = Planet, People, Profit. (Don’t forget the last one.)

Dr. Kent’s first chapter displays a diagram of “The Three Elements of Sustainability.” The first is, indeed, Environmental Sustainability, which involves resource use, environmental management, environmental protection (against pollution), and emissions control.

The second key element is Social Sustainability: human rights, labor practices, safe and healthy work environment, fair operating practices, consumer issues, community involvement and development. This might raise some eyebrows. My own visits to plastics processing plants confirm that many owners and managers of those plants take those issues to heart, but they may not have thought of them as means to ensure Sustainability.

The third element of the triad is Economic Sustainability: profit (yes!), cost reduction, growth and expansion, innovation, investment, owners and other stakeholders, risk management. This part anchors the high-flying ideals of the other components to the basic economic realities of manufacturing business. In my interpretation, it comes down to this: Without a thriving business enterprise there are no people and no resources to pursue the social and environmental goals of sustainability. (Surprise, Guys, who want to save the planet by ridding it of plastics.)

In sum, Sustainability is all about Planet, People & Profit. I don’t see hardly any manufacturers today that operate without attention to all three. So, whether they know it or not, and whether their critics know it or not, they are already on the path to sustainability!

Related Content

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

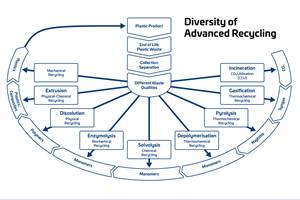

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

Practical Guide to Sustainability Management

New book aims to help plastics processors set and achieve sustainability goals.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)