The Next 'Big' Thing in 3D Printing

Big Area Additive Manufacturing, or BAAM, is attracting entrepreneurs and machinery developers.

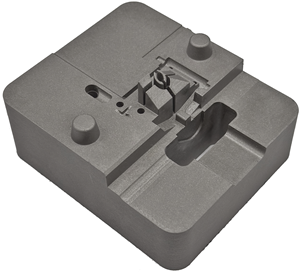

Thermwood's developmental BAAM system with American Kuhne extruder.

Additive manufacturing (AM), better known as 3D printing, is big news these days, and the news in AM is “Big,” as in Big-Area Additive Manufacturing, or BAAM. Visitors to June’s Amerimold exposition in Rosemont, Ill., got an impression of where BAAM is headed. Oak Ridge National Laboratories, Oak Ridge, Tenn., showed off examples of its BAAM work at its Manufacturing Demonstration Facility. ORNL made news this past January with its 3D printed Shelby Cobra sports car, which debuted at the North American Auto Show. At Amerimold, ORNL showed an example of its current thrust in making molds for automotive, aerospace, and other composites fabrication. It exhibited a honeycomb section of mold made from ABS with 20% chopped carbon fiber, deposited by an injection molding-type extruder mounted on a CNC gantry in a machine built by Cincinnati, Inc. Capable of dispensing up to 100 lb/hr, it was described as “FDM on steroids” by Dr. Chad Duty, ORNL group leader for deposition science & technology. FDM is fused deposition modeling, an AM method of depositing a hot, continuous filament of thermoplastic in layers to build up a part. In BAAM, the layers can be around 1/8-in. thick.

Duty estimated that a car hood mold could be built in a “couple of hours” and could then be finished with a conventional gel coat. It could then be used for room-temperature cure of epoxy/carbon fiber composites. He said ORNL is working on PPS, PSU, and PEEK tools capable of withstanding elevated-temperature autoclave molding. It has already tested PPS with 40% carbon fiber. At Amerimold, ORNL also showed off a 35-lb chair made in one piece in half an hour from ABS with 20% carbon fiber. It has been load tested to support up to 600 lb.

Besides the Cincinnati machine, ORNL has worked with a six-axis, articulated-arm robot with a material deposition head. Additional options may be available in the near future. For example, CNC router supplier Thermwood Corp., Dale, Ind., is developing a BAAM machine with a six-axis, gantry-mounted extruder from American Kuhne, Ashaway, R.I. The initial development machine, nearing completion, can make parts up to 10 x 10 ft x 5 ft high. The vertically mounted, 1.75-in. extruder can process over 100 lb/hr. After deposition, a second head on the same machine can machine the part to its final shape.

A second new effort along these lines is a collaborative effort by two firms in Ohio, that are coming at the technology from the extrusion side. Year-old Strangpresse LLC in Youngstown, an extruder builder, is working with Md Plastics of Columbiana, which is supplying special screw, barrel, and check-valve technology derived from injection molding. The goal is to build a vertical, robot-mounted extrusion head that can deposit around 100 lb/hr in a highly controlled fashion. Still in development, the system is designed to ensure highly precise and uniform volumetric deposition of melt as the head moves over a large area at high speed with sudden turns, starts, and stops. The check valve is intended to prevent drool and stringing when deposition stops. The two firms aim to collaborate with a robotics firm to develop a complete BAAM system using a six-axis robot. Expect to hear more on this project in the near future.

Related Content

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More