Total Corbion PLA at K 2019 to Showcase Biobased Innovations

Co-exhibiting with parent Total, Total Corbion will highlight its Luminy PLA portfolio and the most recent application innovations.

As we have been reporting in the last couple of months leading up to next month’s K 2019, a major theme across-the-board will be on sustainability and the ‘Circular Economy’. Biobased materials and additives will certainly be one focus and Total Corbion PLA (U.S. office in New York, N.Y.) which in late 2018 started up its 165 million lb/yr production plant in Rayong, Thailand, a 50/50 joint venture of Total and Corbion of The Netherlands, is one company that will showcase a broad range of its Luminy PLA products and applications.

Last year’s start-up marked a major milestone for both the joint venture and the bioplastics market. With this additional 165 million lb/yr facility, the global production of PLA bioplastics has been increased by nearly 50%, to 480 million lb/yr. PLA is a fast-growing polymer market with an estimated annual growth rate of 10% to 15%.

At the big show, the company will be showcasing a number of partner applications based on PLA to illustrate the range of possibilities offered by this versatile biopolymer. Examples are:

▪ To showcase the high-heat capabilities of PLA, visitors are welcome to enjoy a fresh cup of coffee at the Total Corbion PLA booth served in a PLA thermoformed cup. The cups are available under the naturesse product range by Pacovis. The biobased cups have a reduced carbon footprint compared to PS cups.

▪ In addition to coffee, Clipper tea in PLA-based tea bags and Sant’Anna water in PLA bottles will also be served to visitors.

▪ PLA-lined paper cups, produced by EcNow Tech under their Earth Smart range, will also be on display. Featuring a PLA lining that can withstand boiling water, they are a sustainable alternative to the traditional PE-lined variety based on oil-based plastics. The cups have a lower carbon footprint and can be industrially composted after use (where local facilities exist).

▪ Also on display, coffee capsules for Nespresso machines from ATI and tea bags from Nonwoven Network.

▪ Pepsico and Danimer have developed a compostable PLA/PHA-based potato chip packaging for the Chilean market. PLA/PHA-based drinking straws from Danimer are another innovation that help reduce the environmental impact of plastics.

▪ Also look for PLA-coated paper drinking straws from Shanghai Xinxin and PLA single-use shot glasses by Propac.

▪ A ‘slate-look’ bioplastic thermoformed black platter for attractive presentation of foods such as cheese, sushi and finger food has been developed by Pack & Proper.

▪ PLA pots from organic yoghurt brand Les 2 Vaches (Danone) will be on display, which replace traditional PS yoghurt pots, along with a thermoformed food tray from Cuki Professional.

▪ Biobased and industrially compostable PLA trays for strawberries in the UK have been launched by S&A Group and Voges, as well as compostable PLA breakfast cereal packaging by TIPA in the Netherlands.

▪ Durable innovations include PLA-based butterfly feeders from ABM and Belightful Design, PLA bottle openers from ABM, PLA-based cosmetics jars by Berry Bramlage, PLA computer mouse by Nager-IT and PLA rulers by Pratel in Italy.

▪ Other examples of PLA applications include single-use PLA aprons from Gaia, foamed ice cream packaging from Synprodo, compostable PLA food packaging from Bio4Pack, PLA non-woven applications from Yangtze and PLA toothbrushes from PolyAlloy.

Responsible use of resources is of extreme importance to Total Corbion PLA, say company sources, and this includes optimal end-of-life solutions for PLA applications. The company is active in a number of mechanical and chemical recycling projects, including the re-CUP project where, together with Danone, CITEO, Looplife, Veolia and a few other parties, Total Corbion PLA is exploring the options for collecting and recycling PLA yoghurt cups on the French market. Technical experts will be available at K show on the Total Corbion PLA booth for converters and brand owners who wish to discuss the most sustainable end-of-life scenario for their PLA application.

Related Content

New Cleanroom-Rated Static Eliminator

Neutralize static hands-free in sensitive medical, pharmaceutical and electronic manufacturing operations.

Read MoreHigh-Flow PEI ‘Captures’ Burn-In Test Socket Manufacturer

S. Korea’s Sensata is one of the first BiTS makers to adopt SABIC’s new Superflow Ultem.

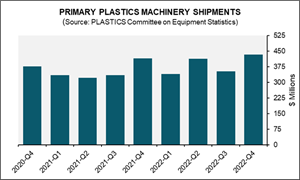

Read MorePlastics Machinery Shipments Rose in 2022’s Final Quarter

The Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES) reported that injection molding and extrusion machinery shipments totaled $432.7 million in Q4.

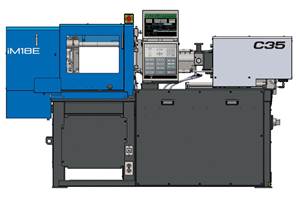

Read MoreCompact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.png;maxWidth=300;quality=90)