Tradeshow Giveaway Converted to Personal Protective Equipment (PPE)

Arburg, Ems-Chemie and Uvex quickly converted darkened, freebie sunglasses into transparent, certified goggles for use by frontline healthcare and emergency workers.

K 2019 seems like eons ago for a lot of reasons—not the least of which being the intervening pandemic—but I still remember Arburg’s executive team donning sunglasses in unison during the company’s pre-K press conference the day prior to the show’s open last October. As the executives ran through the myriad innovations that would be on display in Düsseldorf, they were able to wear one of the applications the company would make that week—Uvex safety sunglasses molded/inspected/packaged in a fully automated cell. A cool “part”, presented in a fun way—it made for a memorable moment. During the show, it made for long lines in Arburg’s booth as attendees queued to grab a pair for themselves.

Arburg’s executive team shows off the Uvex sunglasses the company molded during K 2019.

Fast forward five months, and the manic fun of K has been displaced by claustrophobic quarantine of Covid-19. The sunglasses made another appearance in my inbox, reimagined as safety goggles and another example of the raw ingenuity much of the plastics industry is applying to the pandemic.

A Call for Help

Hearing that the company had produced protective goggles at a recent trade fair, the doctor at the hospital in Rottweil, Germany reached out to Arburg’s Thomas Walther on Monday, March 30 to see if she and her colleagues could be sent some.

Walther, head of application technology, went to Gerhard Böhm, managing director of sales at Arburg, and work began immediately to turn a one-time tradeshow giveaway into much-needed personal protective equipment (PPE) for frontline healthcare and emergency workers in Germany and Switzerland.

The three companies that had collaborated on the goggles for K 2019—Arburg, the Swiss specialty chemicals group Ems-Chemie, and German safety eyewear manufacturer Uvex—joined forces once again. It was decided that production of an initial batch of 20,000 pairs of goggles at Arburg’s headquarters in Lossburg should begin as quickly as possible.

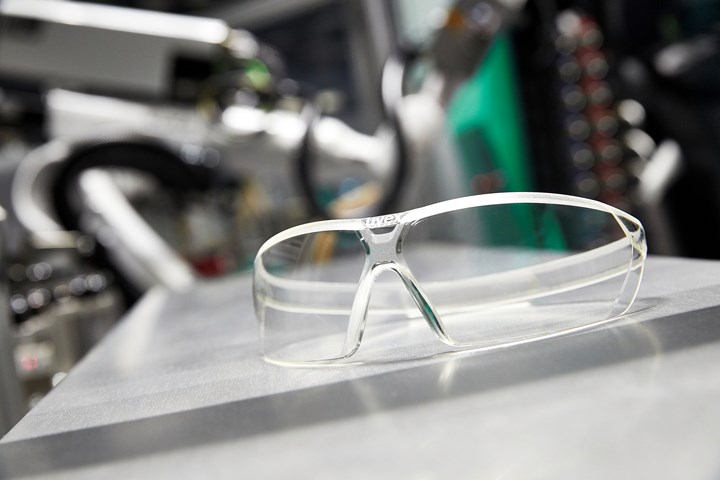

Back in October at K 2019, Arburg showcased fully automated production of sunglasses, using an Allrounder 570 A to mold ready-to-wear sunglasses in a cycle time of 50 seconds. The system included a six-axis robot for the handling, 100% inspection and insertion in fabric bags. The three partners decided that those sunglasses could be transformed into protective goggles, using the same tools and the same design (with a transparent resin).

Ems agreed to the use of the tools; Uvex offered a quick certification; and Arburg set up the production system with removal robot at its new training center in Lossburg. The week before Easter, the goggles began being mass-produced at Arburg’s facility in what it called a “simplified” injection molding process. Exiting the press ready to use, the goggles are packed individually with safety and information data sheets in tubular film bags by hand for final distribution.

Molded by Arburg from Grilamid TR (PA12) donated by Ems-Chemie, the Uvex safety goggles will be distributed to healthcare and emergency workers in Germany and Switzerland in May.

The material for the first batch of goggles, around 500 kilograms (more than 1100 lb) of transparent Grilamid TR (PA12), was provided free of charge by the material manufacturer Ems-Chemie (Domat, Switzerland). Once the eyewear packaging has been CE-marked and assembled, Arburg said “it’s quite likely” that the distribution can begin at the start of May.

As was the case at K, handling and depositing are carried out by a 6-axis robots. Bad parts are sorted out, while good parts are deposited on a cooling station. The packaging is done downstream by hand utilizing a packaging station from Köra Packmat Maschinenbau (Villingendorf, Germany). Arburg and Ems-Chemie will distribute the goggles free of charge via official channels to hospitals, nursing homes and civil defence organizations in Germany and Switzerland.

Read Next

Arburg Opens New Training Center

The training center is part of a new 13,700-m2 structure at the company’s Lossburg headquarters, which will also include administrative space and a health center.

Read MoreArburg ‘Technology Days’-6700 Visitors and Several Novelties

The first metal-powder injection molded smartphone frame, PP-IML containers molded in under 2 sec, a new additive-manufacturing development center, and hints of innovations yet to come.

Read MoreArburg Opens New U.S. Headquarters

Rocky Hill facility includes lab areas dedicated to the Freeformer 3D printer.

Read More