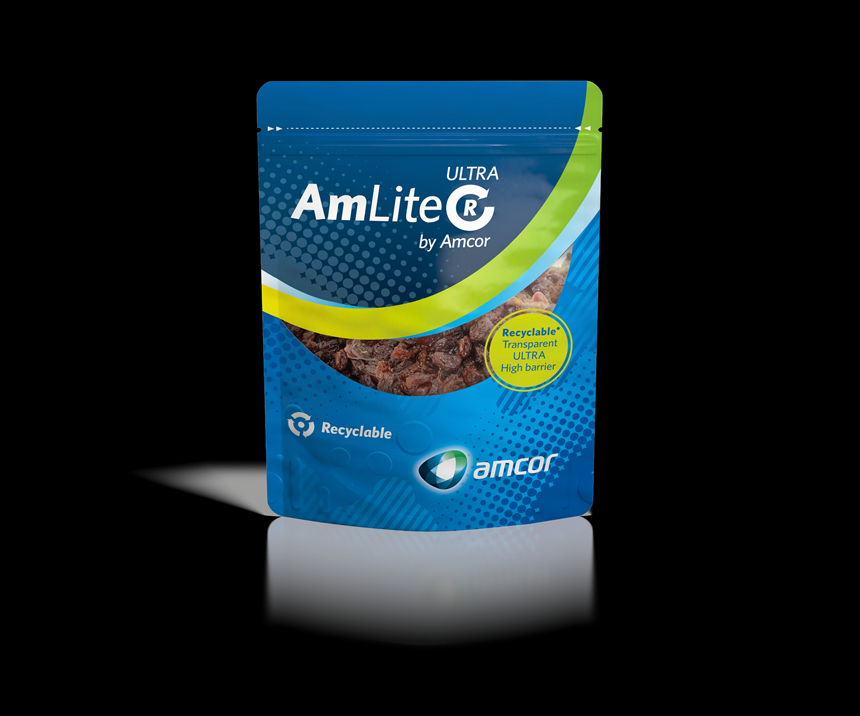

Ultra-Recyclable, High-Barrier PE Film Laminate

Amcor’s AmLite Ultra Recyclable packaging product boasts a carbon footprint reduction of up to 64%.

Amcor has launched its first packaging product made from the company’s revolutionary, more sustainable high-barrier polyolefin film that the company announced last year. The new high-barrier laminate can package a range of food, home and personal care, and pharmaceutical products, and be recycled in existing polyolefin recycling streams.

AmLite Ultra Recyclable is the latest addition to Amcor’s successful AmLite product line, which was first created in 2015 to provide metal-free barrier packaging that significantly reduced the packaging’s carbon footprint. Amcor says the new addition will allow Amcor’s customers to move to recyclable flexible packaging across a variety of consumer-product segments, including coffee, snacks, dry pet food, baby nutrition, pharmaceuticals, and home and personal care. This will be a major shift for brands, as previously, high-barrier flexible packaging was difficult to recycle. To overcome this, Amcor’s R&D team innovated to replace the PET layer of the original AmLite packaging with its breakthrough high-barrier OPP film. To validate recyclability in real conditions, the package is certified by cyclos-HTP Institute, an independent testing lab.

AmLite achieves a reduced carbon footprint by using an ultra-thin, transparent barrier coating to replace aluminum and metallized barriers. That change, combined with recyclability, can reduce a pack’s carbon footprint by up to 64%. "Our recyclable laminate delivers high-barrier protection, can be used on our customers’ filling machines, and can be recycled where polyolefin collection and recycling streams exist," said Luca Zerbini, Vice President of Marketing, Innovation, and Sustainability at Amcor.

PT asked Zerbini for further clarification on the new packaging, as follows:

▪ PT: By using PP instead of PET, you now have an all-polyolefin structure and don’t have to worry about separating PET?

“Correct, the PET has been replaced by PP, making AmLite Ultra Recyclable a full polyolefin material. While PET in formats such as beverage bottles or rigid containers can be recycled, PET in flexible packaging is currently non-recyclable as no recycling streams for this form of PET currently exist.”

▪ PT: Also, by orienting the PP, you increase barrier properties?

“The barrier is provided by a micro-thin coating of our Ultra SiOx barrier technology (basically, it’s like a micro-thin layer of glass applied to the PP). Traditionally, these types of barriers performed well when applied to PET but not when applied to polyolefins like PP, Envisioning a future of recyclable packaging, our R&D team started development on how to replace PET with polyolefins and maintain the barrier performance. The result of this work is AmLite Ultra Recyclable.”

▪ Why are you laminating and not coextruding? .

“We mention ‘lamination’ in our press release announcement because we incorporate barrier into our unique AmLite OPP film and combine it with our customized polyolefin sealant films through lamination.”

Zerbini also offered some further information on the barrier.

“Amcor has focused on developing high performing clear barrier technology for the past several years. The barrier is done using our Ultra SiOx, ultra-thin transparent barrier coating. It is recyclable because the PET layer traditionally used in high barrier packaging has been replaced by PP. The sealant layer is either PP or PE depending on the customer’s need, so you can have a PP/PP structure or PP/PE structure. In both cases, this makes it suitable for recycling in the polyolefin recycling stream such as the one in Germany as well as several other regions in Europe.”. (Note that a traditional PET/PP or PET/PE structure is not currently recyclable anywhere. Unlike rigid plastic bottles, PET in flexible packaging is non-recyclable.)

The AmLite Ultra Recyclable and AmLite Standard Recyclable are the first laminates in the AmLite product range to offer recyclability, adding two products to Amcor’s portfolio. AmLite Standard Recyclable, which provides medium- to high-barrier protection for ambient applications, is already on supermarket shelves thanks to some early adopter brands. AmLite Ultra Recyclable is now available for broader customer trials.

Amcor’s R&D experts are continuing work with new polyolefin films to develop future solutions for even more demanding applications, such as recyclable packaging for retort processing.

Related Content

Fundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MorePrices of All Five Commodity Resins Drop

Factors include slowed demand, more than ample supplier inventories, and lower feedstock costs.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreResin Prices Still Dropping

This downward trajectory is expected to continue, primarily due to slowed demand, lower feedstock costs and adequate-to-ample supplies.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More