U.S. Military Researchers Use Recycled PET For 3D Printing Parts

Researchers said the driving force for this work is to enhance warfare capability and readiness by enabling repairs while deployed and to reduce dependence of the logistical supply chain.

Last year, I reported that NASA is using a machine in space that 3D prints plastic parts and recycles them back into reusable raw materials to make more parts. Well, there’s more development in using reclaimed material for 3D printing, this time from the U.S. military.

The U.S. Army Research Laboratory (ARL) and the U.S. Marine Corps are exploring ways to use recycled plastics for 3D printing parts that soldiers may need on the battlefield, according to a report from the U.S. Army Research Laboratory.

ARL researcher Dr. Nicole Zander and co-collaborator Capt. Anthony Molnar from the U.S. Marine Corps generated fused filament fabrication (FFF filament) from 100-percent recycled PET from bottles without any chemical modifications or additives. Work is also underway to generate filament from other recycled plastics and reinforced filaments.

Zander said that while PET is widely used in many applications, it is not widely used as a feedstock for FFF due to its high melting temperature, water absorption and issues with crystallinity, which can make printing difficult.

The filament was produced on a Thermo Scientific Process 11 co-rotating twin screw extruder. The Process 11 is the smallest scalable twin screw extruder (11 mm) with all the process variables of higher output compounding extruders; yet physically small enough to fit on a table top. “The Army really thought out of the box on this application, turning a troublesome waste product into a valuable resource. This is a strong statement on sustainability,” says Steve Post, business development manager at Thermo Fisher Scientific. Post envisions these units to be suitable for most municipalities as they look for “value ad” in their waste stream providing schools with resources for their 3D printing/additive manufacturing labs.

Zander said recycled PET was shown to be a viable new feedstock, with mechanical properties of printed parts comparable to parts made from commercial filament. In addition to small parts for evaluation, several larger long lead item military parts were also printed with the filament.

"In terms of mechanical properties, most polymers used in FFF have bulk strengths between 30 and 100 MPa. Recycled PET has an average strength of 70 MPa, and thus may be a suitable 3D printing feedstock,” she said.

Mechanical testing, including uniaxial tensile and three-point bending experiments were conducted in the laboratory. In these tests, the tensile strength of 3D-printed recycled PET was compared against commercial filaments and found to have similar strength. In addition, a custom test fixture was made to test a 3D-printed radio bracket (a long-lead military item). Brackets made from recycled PET failed at a similar load to brackets printed with commercial ABS filament. The recycled PET filament may have the capability to replace commercial filament in printing a diverse range of plastic parts.

In addition to mechanical testing, the recycled plastics underwent chemical analysis, thermal stability and a host of other tests.

"Recycled polymers have a variety of different additives, fillers and dyes and may have experienced different processing conditions – even for the same polymer type," Zander said.

To get a better understanding of different recycled plastic feedstocks and the best properties to expect from such materials, chemical, thermal and mechanical analyses were performed.

One reason they focused on recycled PET is because water bottles and packaging are one of the most prolific wastes found on the battlefield. Both U.S. and coalition forces produce large volumes of this waste and being able to repurpose this on location by forward deployed forces could reduce the logistic burden of transporting parts to forward operating bases and the additional costs of disposing of the recyclable material.

Zander and Molnar are in the process of building a mobile recycling facility to enable soldiers to be able to repurpose plastics into feedstocks for 3D printing.

"The MRF will be a plastic processing laboratory housed in a 20 foot ISO container, with all equipment and tools needed to fabricate 3D printing filament from plastic waste," Zander said.

Researchers determined that recycled plastics have shown to be suitable material for 3D printing, provided the material is properly cleaned and dried. The tensile strength of printed parts from recycled PET was equivalent to printed parts made from commercial off the shelf PET pellets and commercial filaments. But the research will not stop here.

"Ultimately, we'd like to produce the best possible feedstock we can from recycled plastics and waste materials," Zander said. "Future work will involve testing 3D-printed long-lead parts against original parts to determine if they can be a suitable long-term or at least a temporary replacement."

The U.S. Army Research Laboratory is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Content

Calculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

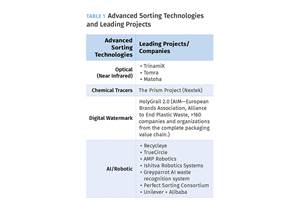

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreA Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More