Video: Peter Neumann's Exit Interview

After 35 years (and 12 K Shows), Engel's Dr. Peter Neumann retired on Dec. 1, handing over the family held company to the next generation—his nephew.

After 35 years (and 12 K Shows), Dr. Peter Neumann stepped down as chairman of injection molding machinery and automation supplier, Engel, on Dec. 1.

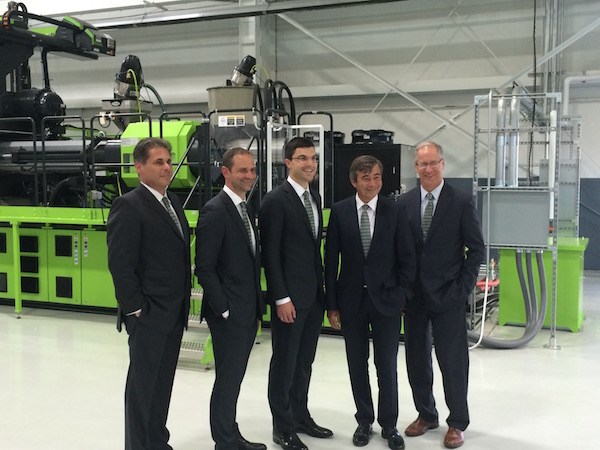

Plastics Technology sat down with Neumann (above, second from right) at his last K as the boss of Engel to discuss what's changed during his tenure; what advice he had for his nephew (above, middle) who's taking the reins; and what he'll do in retirement.

Starting at the company in 1982 in procurement, where he learned about all the technologies that go into a press, Neumann moved through sales and into the executive suite. During his time, the company and the industry expanded its reach globally, specifically into Asia, where Engel has multiple manufacturing sites. It also expanded technologically, from the 8-bit microprocessors of the '80s to the Cloud-backed onboard supercomputers of today's machines.

So what's next? Neumann said he plans on visiting countries apart from those where Engel has offices or customers, as well as sailing, sking, and, go figure, jogging. Weather permitting, his plans for the morning of Dec. 1, his first post-Engel? A morning run.

Related Content

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

-

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

-

Five Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.