What Were the Big Themes in Plastics in 2021?

What stands out in our coverage over the past year? Five main themes are unmistakable, and—spoiler alert!—Recycling was the biggest headliner.

Recycling stories appeared an average of five times per issue in 2021, not to mention other sustainability topics, such as renewable and biodegradable polymers. (Photo: ALPLA)

As the end of the year rolls around, it’s a tempting exercise to look back at what we’ve published in our last 12 issues and what news we might hope to report in the next 12. I’ll save the latter for my next blog (no spoilers!), so here’s a retrospective analysis of a year’s editorial output.

To attempt to consolidate in my mind the content of hundreds of articles written or edited by our staff, I attempted to categorize them under major themes. In flipping through those 13 issues (including a supplement on Technology Trends in May), five key themes struck my eye.

Two of them fall under the umbrella category of Sustainability: Recycling and Renewable/Biodegradable Polymers. Together, and individually, they outweighed the other three categories, with 62 stories I put in the Recycling bin and 28 I planted under Renewable/Biodegradable—90 total. That validated my gut feeling before doing any research: I asked myself, “What was the Big Story of this past year in our plastics coverage?” The obvious answer was Recycling: gathering momentum in PP recycling, commercialization of chemical recycling and solvent recycling, new aids to sortation, expanded offerings of recycle-containing materials, additives to improve PCR quality, capturing and reclaiming ocean plastics and ocean-bound plastics—the steady drumbeat was unmistakable, thanks in large part to the efforts of Senior Editor Heather Caliendo, for whom we created a new beat to ensure consistent coverage proportional to the ever-growing importance of this topic to the health security of the plastics industry.

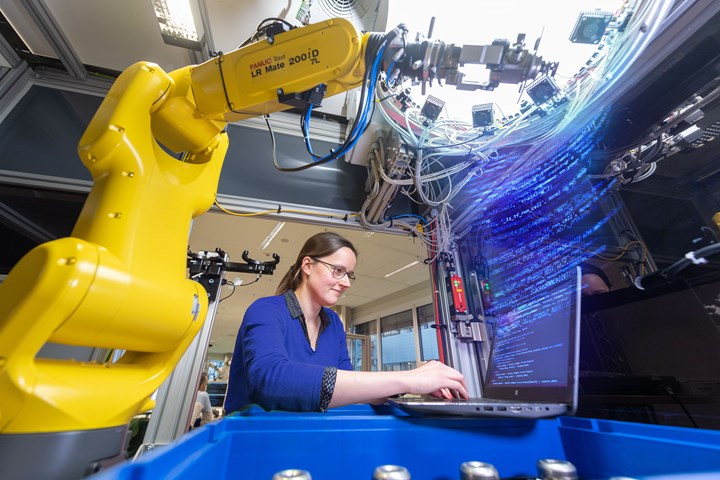

Industry 4.0 (“Smart Factories”) and Automation were the second most prevalent topics in this magazine over the past year. (Photo: Bosch)

Next in prevalence were two closely related fields of Industry 4.0, logging in with 27 stories, and Automation, at 15, for 42 total. Executive Editor Tony Deligio and I have been pounding that beat for several years now, and it’s certainly one of the biggest stories of the decade for this industry.

The remaining big theme of the year was opportunities presented to plastics processors by additive manufacturing or 3D printing. (Photo: Stratasys)

That leaves the new kid on the block, Additive Manufacturing or 3D Printing, which is becoming an invaluable resource for plastics processors, to make plastic parts and prototypes and also tooling. Heather again won this new editorial beat assignment, building up most of the 19 stories published this year.

It’s worth noting that the relative abundance of coverage in each of these five key themes is the same if you count just short news items or just longer stories of a page or more, which tend to address how processors apply these technologies. To me, that’s a sign of good balance.

But ultimately, you get to judge how well our perception of which themes deserve editorial coverage, and in what proportion, matches your reality.

Editors can always defend their choices: “We don’t make the news, we just report it.” However, a wise person once said, “What is news? News is what interests an editor.” That dichotomy defines the challenge of achieving the overarching editorial goal: Relevance.

So you tell us: How well did we hit the target?

Related Content

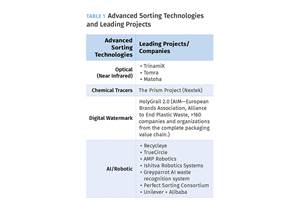

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreSD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

Looking Back on 2021's Major Recycling and 3D Printing Stories

A review of the top recycling and 3D printing stories of 2021.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More