What’s in the Pipeline of New Compounding Machinery Developments at Farrel Pomini

Compounding biopolymers, automatic movement of rotor to seal line, adjustable mixing dam, a twin-screw pump for special applications and more.

I reported recently on my visit to the brand-new headquarters of Farrel Pomini in Ansonia, Conn., for the grand opening of the facility in April. The grand opening event included presentations summarizing the latest technical developments in Continuous Mixers and Compact Processors:

• As reported previously, the company is actively investigating new opportunities in compounding biopolymers such as PLA. Farrel Pomini equipment is seen as appropriate because of its “gentle” treatment such sensitive polymers, with low shear and short residence times.

• The new Farrel Pomini Synergy System, a common framework with common standards for integrating the company’s compounders with third-party equipment and controls in a processing line.

• All systems now have a VPN gateway for remote web-based support in real time. This system can enable Farrel Pomini engineers to adjust machine operating parameters and control limits “on the fly” while a line is running.

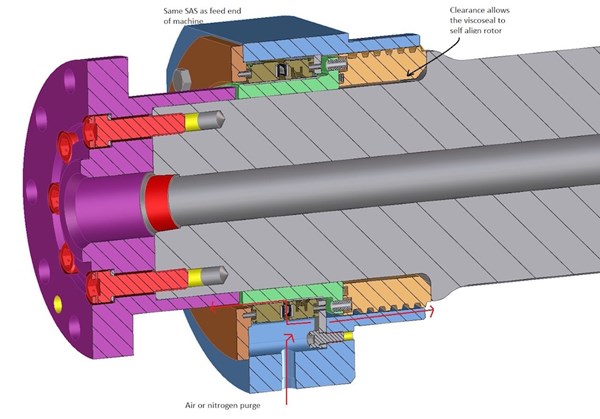

• The newly patented Self-Aligning Seal (SAS) for the feed end of a Continuous Mixer, which was introduced at NPE2015 and is now used on every new machine (and also retrofittable), has been supplemented with a Self-Aligning Viscoseal (SAVS) for the discharge end of the mixer (see image). Like the SAS, the SAVS automatically moves with the rotor to compensate for thermal expansion, rotor wear, and deflection of the rotor by the process material. The SAVS utilizes a melt film for sealing and incorporates a reverse screw thread to retain the melt and prevent leakage. The patent-pending SAVS is still in testing at the Ansonia lab and will enter field testing soon.

• The Slotted Vent Plunger, also introduced in 2015, which provides a larger open area but reduced loss of material, is now standard on new mixers and is also retrofittable.

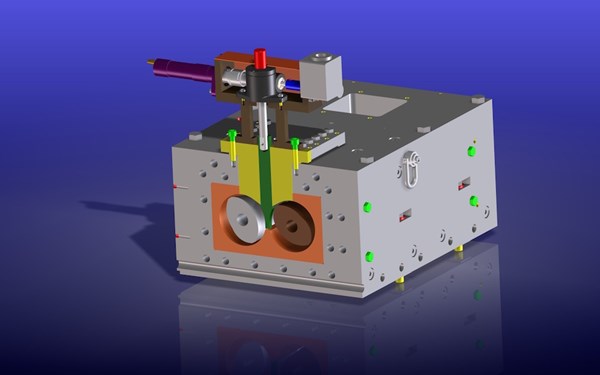

• A new Adjustable Mixing Dam (see image) provides an additional means of varying the amount of shear in the process. Its electronic adjustability eliminates changing out fixed dams between production runs. The company is experimenting with use of the adjustable dam in the upstream mixing chamber of the two-stage CPXL mixer (based on the Pomini LCM design). In this two-stage mixer, the first stage is normally used to combine feed ingredients without melting/fluxing, which occurs in the second stage after addition of further ingredients. But for specialty applications like halogen-free flame-retardant (HFFR) electrical cable, which require either high levels of fillers, special fillers requiring high shear, or heat-sensitive fillers and/or blowing agents, an adjustable dam could be used upstream to start melting in the first mixing chamber, so that additional fillers could be introduced to already melted material in the downstream mixing chamber.

• Farrel Pomini’s R&D on new mixing rotors includes development of a version that imparts a higher level of dispersive mixing. This High-Dispersion Rotor may borrow from the NST rotor design of Farrel Pomini’s Banbury batch mixers (produced by a separate business unit).

• Currently in lab testing is a higher-dispersion #15 rotor for CPXL/LCM machines. It represents a merger of Farrel and Pomini technologies, as the CPXL #15 rotor substitutes a Farrel-type mixing section for the Pomini LCM design in the downstream stage of the mixer.

• The company is exploring the concept of a Twin-Screw Pump for niche applications like PET black Masterbatch (BMB), which contains 30-40% carbon black. Farrel Pomini says it is very difficult to pump and pressurize such a compound, so it may be necessary to substitute a twin-screw for the current single-screw discharge extruder. To prevent oxidation of the PET melt, the mixer and extruder would be close-coupled to eliminate contact with air. The mixer would utilize the new CPXL #15 rotor with multiple adjustable dams.

Related Content

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreSustainability Among the Many Niches at Niche Polymer

Founded in 1987, Niche Polymer continues to grow—both organically and through acquisition—by focusing its product-development efforts on ever-changing market needs. Adding value to both industrial and post-consumer scrap is a growing part of this effort.

Read MoreLFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreRead Next

Farrel Pomini Debuts New HQ For Continuous Compounding

More than 50 visitors were given a tour of Farrel Pomini's new headquarters for continuous compounding systems in Ansonia, Conn.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)