Winners of SPE Auto Innovation Awards Wow with Many ‘Firsts’

Innovative, transferable, and intelligent use of plastics shine in nine categories.

Celebrating the 47th annual Automotive Innovation Awards Competition at its gala last month in Livonia, Mich., SPE’s Automotive Division, announced the winners of this year’s nine categories. This competition, for which I was honored to be a participating judge for the third consecutive year, is the oldest and largest recognition event in the automotive and plastics industries.

Take a look at this year’s winners, starting with this year’s Grand Award winner—also the winner of the Body Exterior category. Of the nine winners, all but one category entailed the use of thermoplastics. In subsequent blogs, I will highlight some of the other contenders in the various categories that definitely merit attention.

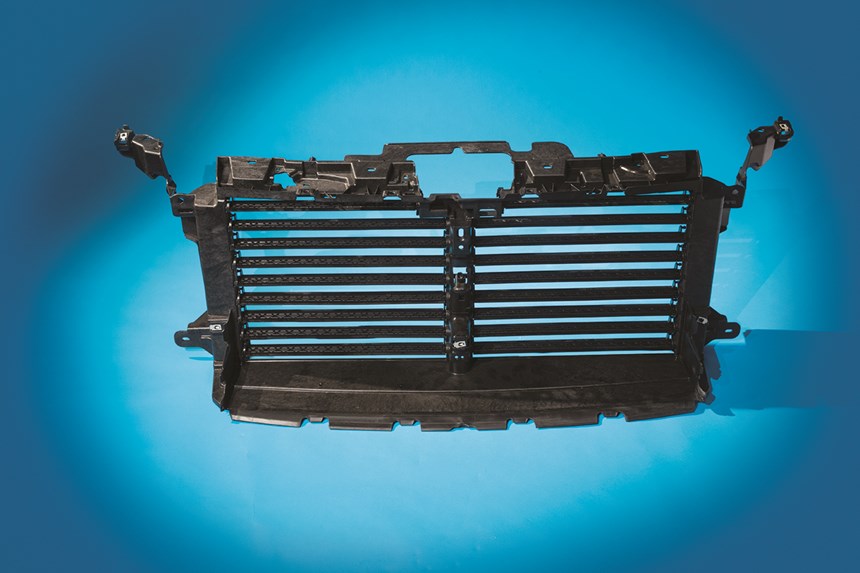

Body Exterior/Grand Award Winner—PP LFT Structural Active Grille Shutter w/ Integrated Loose Layer Construction

The part, which appears in the 2018 Ford Expedition luxury SUV, is said to be the largest two-shot structural active grille shutter (AGS) in production today. It was designed with an integrated locating and attaching system for consistent fit between the grill and headlamps, which eliminates the need for FEM (finite element analysis) assembly, dunnage and shipping. The material used by injection molder Magna Plastcoat is Celstran 40% long-glass PP from Celanese Engineered Materials, Irving, Texas.

The use of LFRT (long-fiber-reinforced thermoplastic) to develop a structure with PP offset an estimated 3 lb of weight over alternative metal and nylon hybrid designs considered. An equivalent steel structure would weigh 18 lb more that the LFRT design, which delivers the required durability. In addition to reducing variable and piece costs by an estimated $5 with an entirely thermoplastic solution, the enhanced design achieved $16 internal assembly-cost reduction per vehicle and eliminated around $45 auxiliary costs. Improved parts consolidation also phased out the need for four separate fasteners and associated labor. Ford will be using similar parts on all of its trucks.

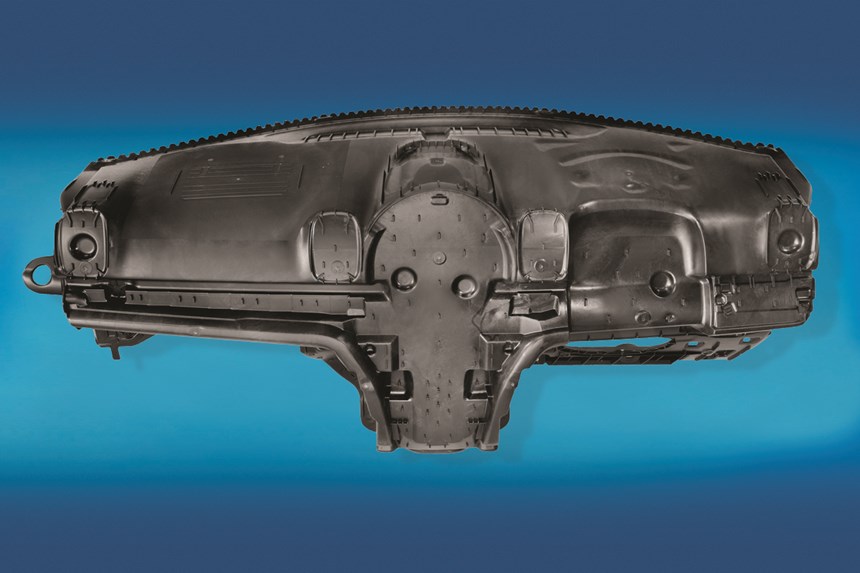

Body Interior—LGF PP Instrument Panel Carrier

The instrument panel (IP) carrier in the 2017 BMW Mini Countryman utilizes Stamax 60YK270E, a high-flow long-glass fiber (LGF) PP copolymer from SABIC. The LGF PP injection molding via structural chemical foaming with core-back process, produced by International Automotive Components (IAC), enabled the production of this part with very low VOC emissions, meeting VDA 278 specifications.

With use of the LGF PP copolymer, a 1.9 mm thin-wall stock was achieved, increasing stiffness at lower weight. Extensive CAE work predicting warpage of the foamed part provided valuable insights, allowing for the modifications of tooling in advance. Use of foaming resulted in a 15% weight-out versus comparable solid application, fewer emissions and fuel consumption savings. Going forward, BMW and partners see this as an industry benchmark for IP carriers.

Chassis/Hardware—Powertrain Mounting Clevis Bracket

Appearing on the 2017 GM Cadillac XT5 crossover SUV, this engine clevis bracket is reportedly the first composite mount designed for a 6-cylinder engine, passing peak loads of 25 Kilo-newtons of force. Injection molded by Hutchinson, the part is made from Ultramid A3WG10 CR BK00564, a 50% glass-reinforced nylon 66 from BASF. It replaces metallic solutions (stamping, welding and die-casting) used previously, resulting in a 45% weight reduction.

NVH (noise, vibration and harshness) was also improved due to the damping characteristics of the nylon compared to aluminum. In fact, the nylon matrix, acting as a dashpot, offers ten times the damping vs. aluminum and even at elevated temperatures. Corrosion resistance is improved, and the part can be recycled at end of life. Seven clevis brackets were developed for different powertrain combinations with no warranty claims after 1.5 years of production.

Materials—Low-Friction Polymer for Chain Tensioner Arms

The use of Stanyl HGR2, a nylon 46 from DSM Engineered Plastics modified with PTFE for enhanced stiffness is featured on the 2017 Ford F-150 pickup and Ford Mustang sports car. The material was a drop-in replacement for nylon 66 in vehicles powered by a 5.0L V8 engine for enhanced wear and friction performance. The resultant fuel economy savings (0.4%) from rotational torque reduction in the cam-shaft (0.5Nm) was equivalent to a 40lb weight reduction, and at 1/10th the cost.

Annual environmental benefits include reduction in gas consumption by 12,000 barrels and greenhouse emissions by 5000 tons. This innovation is highly transferable, to provide affordable fuel economy improvement, and will be utilized on more Ford vehicles, beginning in 2018. The total potential environmental impact of translations across vehicle programs at Ford may be multiple times the values notes for the Mustang and F-150.

Powertrain—Turbo Charger Outlet T-Joint

Featured on the 2018 Hyundai Genesis G80 and Kia Stinger sedans, this part is injection molded with Zytel XT, a new 35% glass fiber reinforced, heat-stabilized nylon 66 which was developed for good retention properties over time at temperatures up to 220 C/428 F by DuPont (now, DowDupont). Molded by Hwaseung R&A, Ltd. this plastic turbo charger outlet T-joint achieves a 42% weight savings and a 35% cost reduction, along with improved airflow, reducing the pressure drop (-8kPa) to increase fuel economy and improve NVH performance compared to the previous aluminum die cast part.

Airflow noise is also reduced and long-term durability increased via the rib pattern design. Special three-gate positioning tooling was designed to minimize stress in weld-line area for strength and durability and for processing optimization.

Process/Assembly/Enabling Technologies—Two-Shot Interior Decoration Bezel

This unique 3-D decorative effect, which appears in the 2018 Ford Fiesta subcompact, is achieved with rotary two-shot ‘reverse’ injection molding (1st shot is Infinol LT1220 tinted PC) with overmolding of textured/grained surface with 2nd shot (self-colored effect pigmented ABS) from Lotte Advanced Materials. The grain is lasered into the mold.

Tier supplier Faurecia Interior Systems molded the part which represents the first time this process was used to achieve the 3-D visual effect (color and texture) for a part of this size and geometry. A 30% cost savings was achieved versus IMD/IML/high-gloss painting and there was a 20% scrap reduction versus conventional two-layer high gloss piano black appearance.

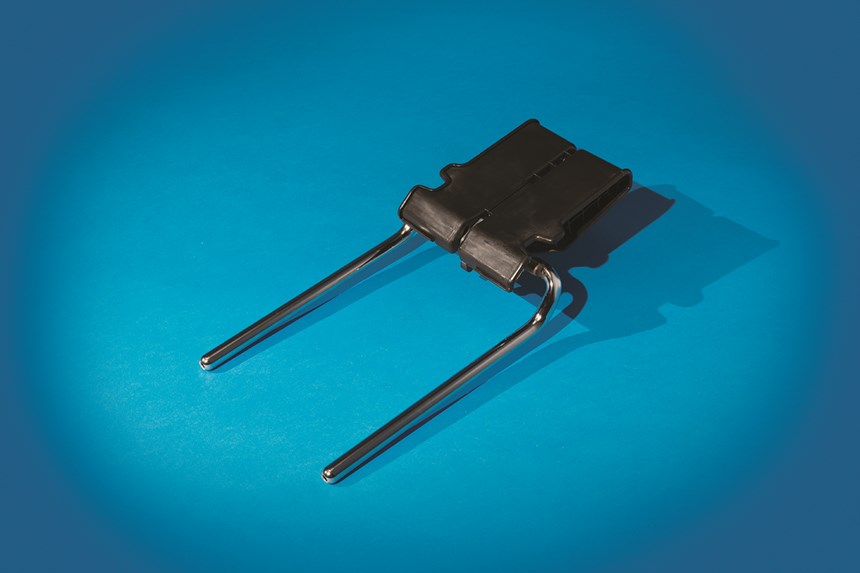

Safety—Third Generation 4-Way Head Restraint

This low-cost, low-mass head restraint is featured on the 2018 Ford F-150 pickup is made from Hylon N1000STHL nylon 66 from Ravago Manufacturing Americas and injection molded by Windsor Machine and Stamping. It provides exceptional rigidity for whiplash protection. Its flexible design allows the front surface of the head restraint to be translated closer to or further from the occupant by 60 mm with incurred costs (allowing for the precise balancing of comfort and safety).

Replacing steel with plastic as the primary load bearing component is new to front-row head restraints. The part design eliminates manufacturing complexity making use of intelligent geometries so that readily available materials could be used. A $10.73 million savings ($2.80/vehicle) is projected by the end of 2020 as this technology is extended to new vehicle programs.

Aftermarket—Integrated Floor Bedliner Divider

Designed for GM’s 2017 Chevrolet Silverado pickup, this ‘first time’ twin-sheet thermoformed bedliner divider is integrated into the bedliner as one piece. By not having to manufacture a separate floor divider part, there was a cost savings of $275. This divider, manufactured by Penda Corp./Penda Durakon, is made of A. Schulman’s TPP 1026EU TPO. It incorporates a molded-in locking feature to secure the divider into the truck wall when it is raised.

The divider eliminates the need for a cargo net or separate divider allowing the user the put smaller items in the bed without having them move and slide around when the vehicle is in motion. Dual textures are achieved on both sides of the part. The key innovation is that the grain appearance—made in the tool—is achieved throughout the thermoforming process with lower capital investment and improved timing over injection molded bedliners. Added part thickness of this bedliner as a result of twin-sheet thermoforming enabled the divider to be integrated into the bedliner floor—which could not be done with a traditional thermoformed bedliner. The design can be applied to different vehicle models and brands via an insert for different logos.

Environmental—Next-Generation Bio PUR Foam for Instrument Panels

Featured in the 2018 Ford Fusion sedan, this IP application provides a sustainable alternative to conventional petroleum based foams—at lower weight, cost, and with more design flexibility. This next-generation castor oil-based polyurethane (PUR) foam—made from Elastoflex 3496/102 PUR from BASF, provides for lower molded density, the ability to be foamed in as little as 4 mm cross sections, and superior bond strength to mating materials.

Foam-in-place tooling—where a cast PVC, TPE, or TPU skin is placed in the mold with a hard plastic retainer and the foam is injected between these two components, is used for processing by International Automotive Components (IAC). A weight savings of 20-40% (depending on foam thickness) and a cost savings of $2 per average foamed-in-place IP is achieved.

Related Content

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MorePrices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More