EXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

Dies should be designed to deliver polymer from their entrance to all points at their exit with the same pressure drop. This results in a shape exiting the die at the same velocity at all points in its cross-section to form the desired shape. If the polymer does not exit at the same velocity across its cross-section, it is distorted from the desired shape to accommodate the varying velocities.

In order to accomplish uniform exit velocity, it is necessary to design the entire length and cross-section of the die while considering the viscosity at all points to calculate the pressure drops from entrance to exit. This is greatly complicated by the fact that polymers display non-Newtonian behavior, meaning their viscosity varies with shear rate.

At any specific output, the viscosity is defined by the force applied over the area divided by the velocity over the channel depth, or more simply the shear stress divided by the shear rate. Notice the words at any specific output, meaning that the viscosity changes throughout the die when the output changes. And not only does it change, it does so not in a linear or proportional manner, but in a logarithmic relationship to the shear rate.

This means that a die is designed by necessity for one specific output and one specific polymer. In other words, it’s only optimum at one output and one polymer. Yet I have found that many extrusion processors consider dies as “general-purpose” tools suitable for an infinite variety of outputs and polymers. They figure that the adjusting screws with which dies can be equipped may be used as a means of manipulating or “correcting” the die flow.

That just isn’t so. If you want to correct the die flow, the only way is to remachine its internal surface(s), period. True, die designers have added a few built-in adjustment features that give processors a finite amount of flexibility to accommodate different outputs and polymers (provided the polymers have similar viscosity-to-shear-rate relationships). But if you’re looking for infinite flexibility in output and polymer selection, expect some serious repercussions. Round or annular dies are generally more flexible than profile or flat dies, but even those designs can be limited in versatility.

These flexibility-enhancing adjustments often introduce undesirable characteristics into the extruded shape. Substantial changes in the flow pattern of the die can change molecular orientation, which affects shrinkage and warpage upon cooling and contributes to poor gauge control. In many extruded parts, changes in die-flow pattern can also adversely affect physical properties.

Polymers exhibiting the least non-Newtonian behavior have the greatest range in output variation because their change in viscosity is less affected by shear rate. That property can be defined by the power law coefficient, which is essentially the slope of the relationship between shear rate and viscosity. The higher the number, the less shear-sensitive is the polymer.

For example, PC and PET—having a high power law coefficient—are more flexible in accommodating output changes without significantly affecting die flow, while PVC—with a low power law coefficient—would be less accommodating.

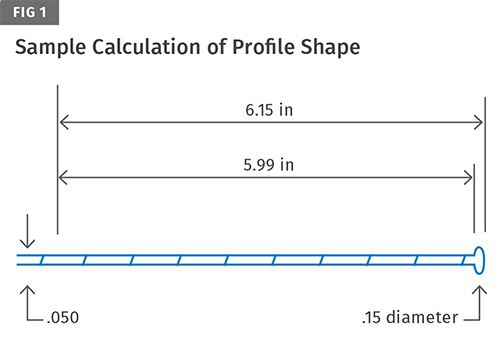

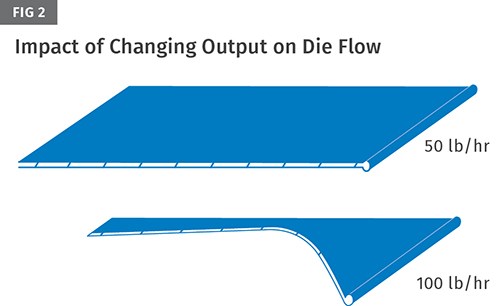

As an example of how output changes the die flow, I did a trial calculation on a profile shape having the dimensions shown in Fig. 1. Assuming the die was balanced behind the exit to produce a uniform profile at 50 lb/hr of PP with a melt flow rate of 5 g/10 min, changing output to 100 lb/hr distorted the profile as shown in Fig. 2.

Because the flow in the circular area had lower shear rates, the viscosity was reduced proportionally more in that area than in the slit area when doubling the output.

There is an unbalancing effect on flow velocity with output change on almost all dies, but it is generally less pronounced in round or annular dies because of their natural symmetry. Poor die balance is the cause of many defects, such as folds, wrinkles, uneven shrinkage, warpage, poor surface, and rippled edges. In coextrusion you will have all these problems plus the additional one of distorting the cap layer(s). Die design is even less forgiving in coextrusion.

There is no universal or general-purpose die for polymer extrusion. A great deal of expertise goes into the design of most dies. With modern computer modeling techniques, thousands of calculations can be made in seconds to make the die very precise for a given output and polymer. That still does not give it a great deal of flexibility.

If you use dies for multiple outputs and applications, many of your quality issues could be related back to not having a die suited to the application.

Related Content

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More.jpg;width=70;height=70;mode=crop)