Extrusion & Thermal Properties: Not Just for the Lab Guys

Do you really need to know how thermal properties of polymers affect extrusion?

Do you really need to know how thermal properties of polymers affect extrusion? Isn’t this stuff just for the guys in the lab? Yes and no. To troubleshoot many processing issues, you’ll need at least a basic understanding of how polymer thermal properties impact your process—from the feed hopper through the final product dimensions. Much of this data is hard to come by. But to understand many aspects of equipment performance, you should bone up on key polymer properties that usually aren’t available in data sheets:

- Viscosity vs. shear rate data at several temperatures in the processing range.

- Specific heat.

- Thermal conductivity.

- Solid and melt density or their specific weights.

- Melting point or processing temperature.

Viscosity affects melting rate, output, melt temperature and die flow, among other things. The higher the viscosity, the higher the melting rate in the screw, extruder power usage, discharge pressure, and melt temperature. In order to determine the viscosity ranges of your materials, you’ll need data from a rheometer, which applies differing loads to develop various shear rates. The rheometer can also be run at various temperatures to show how polymer viscosity responds to changes in both shear rate and temperature. Polymers such as PP are quite shear sensitive, meaning the higher the relative velocities in the screw or flow channel, the more the viscosity decreases. Other polymers such as PET are more temperature sensitive, meaning the viscosity changes a lot with temperature. Some polymers are considered to be both shear and temperature sensitive.

Specific heat defines how much energy it takes to raise the temperature of a polymer. HDPE, for example, requires an average of 0.55 BTU/lb-°F, while HIPS requires 0.4 BTU/lb-°F. Therefore, it takes almost 40% more energy to raise the temperature of 1 lb of HDPE than 1 lb of HIPS. This means more drive power is required to process HDPE than HIPS at the same lb/hr and the same melt temperature. It also takes 40% more cooling capacity to extract that heat from HDPE, which means larger cooling rolls for sheet and flat film and longer spray tanks for pipe, tubing, and profiles.

Thermal conductivity is the ability of the polymer to conduct heat. Polymers with high thermal conductivity melt easier and cool faster. For example, HDPE has an average thermal conductivity of 0.15 BTU/ft-°F-hr, while HIPS is 0.08 BTU/ft-°F-hr. Because of its higher thermal conductivity, HDPE melts more easily from heat transferred from the surrounding melted polymer or from the barrel. Likewise, it is more difficult to cool HIPS of the same thickness and temperature because of its lower thermal conductivity.

Solid and melt density are particularly important in screw design and extruder sizing. Some polymers have a modest change in density as they soften or melt, while others change significantly. Typically, crystalline polymers have a much larger change in density during processing than amorphous polymers. HDPE (crystalline) density changes 18% from 0.95 to 0.78 g/cc when melted, while HIPS (amorphous) changes only 15% from 1.04 to 0.88 g/cc when raised to the processing temperature. This means that a specific screw design would be expected to have a slightly lower lb/hr output with HDPE than HIPS, since screw output is volumetric. This change in density has to be calculated into a screw design.

Melting point can be confusing, as only crystalline polymers have a defined melting point, while amorphous polymers simply soften as they get hotter. As a result, it is best to compare polymers by their typical extrusion processing temperatures. By multiplying the specific heat and the temperature rise necessary to heat polymers to their processing temperature, you can estimate the relative power required to process various polymers. This data is important in the design of the screw and the sizing of the extruder drive.

Thermal diffusivity is a combination of the thermal conductivity divided by the specific weight and specific heat. Specific weight is the density multiplied by 64.43 lb/ft³, which is the weight of a cubic foot of water. Diffusivity combines three thermal properties to provide a reference for the energy necessary to reach the processing temperature at a specific thickness and the cooling necessary for removing that heat. For example, the diffusivity for HDPE and HIPS are 0.0046 and 0.0031, respectively. This result shows that it is almost 50% more difficult to add or remove heat from HIPS than HDPE.

The more you know about polymer properties the easier it will be to quickly find the correct answer to many processing problems.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

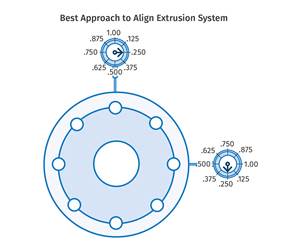

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.jpg;width=70;height=70;mode=crop)