Get Smarter on Extruder Sizes

Extrusion Know How

Processors tend to recommend a much larger extruder than what’s really necessary for the job and the capabilities of the downstream equipment.

Knowing that customer requirements change continuously and output improvements are always being pursued, operating people nowadays tend to recommend a much larger extruder than what’s really necessary for the job and the capabilities of the downstream equipment. While getting an oversized extruder provides “just-in-case” flexibility, it can also result in much higher daily operating costs. Let’s take a look at why.

Both AC and DC drives have a higher power usage per pound of output at low speeds. DC drives are even more expensive to operate than AC drives at low speeds because of their additional disadvantage of poor power factor at low speed. The larger extruder increases thermal losses to the environment because the latter are proportional to the heated surface area of the extruder. This can be useful in cold weather to heat the plant, but it is a major cost factor in warm weather, particularly if it requires use of air conditioning.

The electrical requirements for heat-up and temperature maintenance are also proportional to the extruder’s mass. Heat-up time can double from one extruder size to the next. Although not usually a major cost factor, larger extruders also require more floor space. More importantly, they also require larger-capacity utilities with higher expenses associated with installation and maintenance.

Another important cost factor is the extra time it takes to start up and change over a larger extruder. This extra time results in lost production and generation of larger amounts of scrap. Even routine changeovers requiring purging are more expensive, as much more purge material is required to change materials or colors.

Naturally the capital investment expense goes up with machine size, and that has to be amortized into the production cost. Moving up one extruder size roughly doubles the installed capital investment. At equivalent outputs, larger extruders have more residence time and have more material inside, increasing the likelihood of degradation as well as the amount of degraded polymer.

Simply put, extruder size needs to be considered in the daily economics of producing extruded products. For example, operating a 4.5-in. extruder at 1000 lb/hr and a 6-in. extruder at the same output can result in a 50-100% increase in total operating cost, depending on the particulars of the equipment, electrical cost, number of changeovers, and polymers being processed.

Deciding on the right extruder size is also important when deploying the extruders you already have in place. Many times, I have seen little or no thought going into the selection of the most economical extruder. Recently I saw thin-gauge, narrow PET sheet being run on a 6-in., 34:1 extruder with a 500-hp drive. The screw speed was 36 rpm with a maximum of 125 rpm. Sitting nearby was an older 4.5-in, 30:1 extruder with 200 hp that would have done fine. But the processor preferred the new line because it was easier to operate. Here the hourly operating cost was approximately twice what it could/should have been.

Picking the right size extruder is pretty much a function of the output at a reasonable screw speed. The proper L/D ratio depends on the requirements for mixing, venting, and pressure generation. Horsepower is a function of output and the polymer being processed and can be easily calculated. However, this can be a rather complex matrix of choices, and decisions should be left to experts.

My advice is to develop an hourly operating cost for each extrusion line and try to fit production to the least expensive line as a part of the scheduling procedure.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

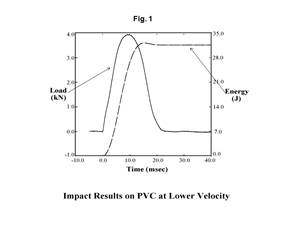

Read MoreThe Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More.png;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)