How Fillers Impact Extrusion Processing

Their addition can significantly change the processing properties of a polymer.

The addition of fillers can significantly change the processing properties of a polymer. Refer to general melting-rate calculations for viscous dissipation in single-screw extruders (shear melting) and you’ll see this clearly. Viscous dissipation is increased with increasing viscosity, density, and thermal conductivity, and by decreasing specific heat.

Adding fillers to the polymer mix affects all of these parameters. The generation of heat in the polymer itself depends on its thermal properties, viscosity, and the conductive heat transfer to or from the extruder. By adding most fillers, the amount of energy required for viscous dissipation is greatly reduced in relation to the mass output.

Polymers are poor conductors of heat compared with mineral or glass fillers. Moreover, polymers require more energy to raise their temperature (specific heat). Additionally, most fillers have a significantly greater density than the common polymers, giving them more “thermal bulk.” Finally, addition of fillers usually increases the compound’s viscosity as compared with the neat polymer.

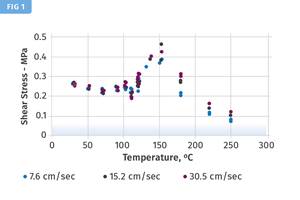

MORE VISCOSITY=MORE SHEAR STRESS

Increasing viscosity increases the shear stress in the extruder, which is the basis of the mechanical-to-thermal energy conversion in a single-screw extruder. Stated simply, much of the effect of fillers in a single screw extruder can be described by a combination thermal property called diffusivity.

Diffusivity is a good indicator of the ability to raise the temperature and the ability to transfer heat.

Diffusivity=Thermal Conductivity/(Specific Heat x Density)

The units in the SI system are:

m2/sec=W/(m °K) ÷ J/(kg °K) x (kg/m3)

Information on materials’ thermal properties can be found on the internet and a relatively accurate average of each thermal property for the polymer and fillers can be determined by simple proportioning of the thermal properties to the mix percentage.

As an example, a polypropylene filled with 40% calcium carbonate would have a diffusivity approximately 3.5 times greater than that of neat PP. This means it will take much less energy from the extruder drive and will transfer energy much faster than the neat PP in relation to the mass of the output. This means lower motor load and quicker, more uniform melting than neat PP at the same output (lb/hr).

Higher diffusivity has implications throughout the whole process. As noted, the extruder drive load will be lower at the same output and the melt temperature will be more uniform. Cooling will be easier for the same reason. Heat will go in faster and easier and will come out faster and easier.

MORE SENSITIVE PROCESSING

This all sounds favorable at first glance, but the ability to raise or lower the temperature more easily and quickly can make the process more sensitive. Compensation has to be made in the operating conditions, often requiring some equipment changes, when running highly filled polymers. Since heat transfer is greatly improved, the barrel-temperature profile becomes more sensitive, for example.

The flow through adapters and dies also becomes more sensitive; the greatly increased diffusivity of the polymer will cause it to change temperature and resultant viscosity much more quickly when passing through these areas. This can cause variations in flow, particularly when there is frequent and significant cycling of the heat zones.

This is particularly important in multiple-exit die systems or where the flow is spread out, such as in large sheet or film dies, and in profile dies having large variation in cross-section.

The characteristic of filled polymers to heat and cool more easily can result in variations in product quality such as distortion, surface finish, and geometry, requiring changes in tooling, cooling rate, and line speed when changing from neat polymer.

Estimate the magnitude of these effects when running filled polymers by the use of the diffusivity term as a method of categorizing different levels and types of fillers

Related Content

How to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreOptimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)