INJECTION MOLDING: How Different Machine Types Handle Fill and Pack/Hold Times

The procedures are different between series and parallel machines. What type do you have? How can you tell? Here’s what you need to know.

Running an injection molding machine and documenting a process so that it can be run to produce the same parts on the same or a different machine can be a challenge. It is rather interesting that each molding shop has its own version of a setup sheet. You’d think in this day and age, with something so important, there would be some standards and consistency.

What should be in a setup sheet to document a process is too large a topic for one article, but there is one aspect that recently came up during a training session that needs attention: How different machines handle first- and second-stage injection. Depending on the brand of machine you are using you can put the same numbers into the controller and get different results. Let me elaborate.

Let’s say you want to run a job on two different presses, machine “A” and machine “B.” Please understand this has nothing to do with the quality of either machine. The focus here is on how their respective controllers handle first and second stage (fill and pack/hold). One is not better than the other, but there are operational differences.

In this example we will put into each controller the same numbers for injection time and hold or pack time. Both machines are set up with 9 sec for injection time and 7 sec of hold or pack time, also known as second stage. In both cases, with appropriate shot-size and velocity settings, the actual fill time is 3.60 sec. That is, both machines are set up to provide an identical fill time for our part—same size, and weight for first stage; no pack. Keeping fill time the same is critical for making identical parts, so no problem on the first stage. Also, let’s stipulate that the gate-seal time is 6 sec to make a good part. The question for this example is: Do we have the same process, particularly the same hold/pack time? The answer requires understanding how each of these machines sequence the first and second (pack/hold) stages.

Machine “A” is what I call a series or sequence-timing machine and Machine “B” is a parallel-timing machine. Both machines transfer from first stage (fill) to second stage (pack/hold) via position transfer/stroke cutoff. The parts at the end of the first stage for both machines are identical visually and in weight and size. It is the second stage that is different.

For machine “A” there is 7 sec of second-stage (pack/hold) time, and for machine “B” second-stage time is equal to 9-3.60 sec or 5.4 sec. Hence the “B” process has no gate seal and a different, smaller/ lighter part. Machine “B” actually has a different meaning for injection time. Machine “B” injection time is actually a total injection-forward timer. It is the total injection-forward time for first and second stage. You can put any number you want for total second-stage time, but you will get a hold time equal to the injection-time setting minus the fill time.

This is different than machine “A,” which handles the sequence differently. Once the screw reached the cutoff position at the fill time of 3.6 sec, the remaining time on the first-stage timer is not used; the machine sequences to the second-stage timer and uses it for timing the second stage. As you switch from type “A” to “B” you changed the plastic variables even though the machine setpoints were the same. So what type of machines do you have? How can you tell?

The best way to analyze a pressure vs. time (not position) graph or curve is to see how long the second stage stays on. Or you could find your machine in the table on p. 20. This is not something you can look up on the internet (at least not until this article is posted on PTonline.com). So I thought it might be useful to provide this information for the machines with which I am familiar. Let me know if I have any listed wrongly.

If you have a type “A” machine, a more proper setting for injection time in this case is about 3.75 sec—not the 9 sec used in the example above. If the machine does not reach position transfer or stroke cutoff by the correct fill time of 3.6 sec, something is wrong; maybe a gate is blocked and the first stage needs to be ended. Alternatively, if you brought this injection time over to a type “B” machine, you would have only 0.15 sec of hold no matter what the set hold-time number is. That would really foul up the process.

All of this may be old hat for seasoned processors, but for new folks—and even seasoned “C rustys” in the heat of production—this subtle difference can get lost as fires are fought from one machine to another. It is an easy mistake to make. In fact I would go as far to recommend that you equip your plant with all of one type or the other, if possible.

In short, use plastic variables or numbers and know your machine.

ABOUT THE AUTHOR

John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. E-mail john@scientificmolding.com or visit scientificmolding.com.

Related Content

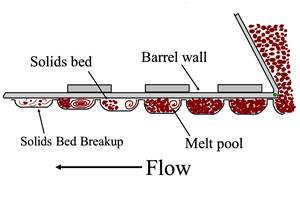

Improve Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More

.jpg;width=70;height=70;mode=crop)