Injection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

During the introduction of my seminars, I use a slide developed by Glenn Beall to define injection molding. The definition reads:

“Injection molding is a jungle of disconnected facts and fairy tales.”

There is some truth to this statement. As proof, we are going discuss and provide some interesting data about “backpressure.” We will start with defining what backpressure is and go on to what it does and does not do.

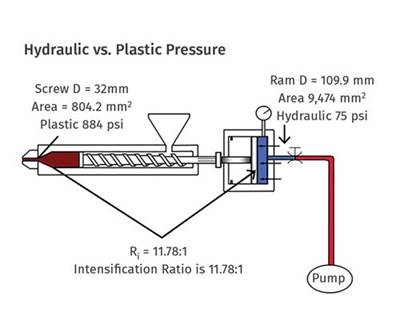

Backpressure is generated by the metering section of the screw. The metering section is typically the front five flights of a general-purpose 20:1 L/D screw. Its function is to pump uniformly melted plastic through the check valve into the front of the barrel. This pumping action fills the front of the barrel with the volume of plastic required to make the shot size appropriate for the part(s). Simultaneously, this pumping action normally develops 300 to ~1500 psi (20–103 bar) of pressure on the molten plastic. Please remember that if you are using a hydraulic machine you must use the machine’s intensification ratio to calculate the plastic pressure in the front of the barrel. That is, multiply the hydraulic oil pressure by the machine’s intensification ratio. Note: It is rarely 10:1 today.

Why do we need these pressures? My reasons include:

- Better melt-temperature control (not increasing melt temperature);

- Better melt uniformity in viscosity and temperature.

- Good color and additive blending, if done at the press and with a correctly designed screw;

- Better shot-size control;

- Better filling of the flights to prevent black specks and degradation where the flights meet the root diameter of the screw;

- Prevent screw augering due to pellets being wedged between flight land and feed throat.

There are times you should use lower backpressure, which can prevent the following:

- Vent flooding in a vented barrel;

- Fiber breakage in reinforced resins;

- Degradation of resins such as PVC and acetal, if you have to use high screw speeds (rpm);

Lower backpressure can also help minimize screw-recovery time when it is the determining factor in cycle time. However, as important as short cycles are to production and profits, the part is worthless if it is not acceptable to the customer.

Note that I did not say the purpose of backpressure is to raise the temperature of the resin. Most of us were trained that if you wanted to raise the melt temperature during processing, just increase the backpressure. I bought into it early on, but as a proponent of “Scientific Molding,” I live by the rule you must have data. Therefore, early in my career when I worked in technical service and had a molding lab available, I did the experiment of changing the backpressure and checking the melt temperature.

Temperature measurement was with a preheated probe (not recommended today) and I never saw the assumed rise or fall of melt temperature. Since this was so ingrained in nearly all the processors I knew, I did not have the will to counter everyone’s assumption.

Questions about Injection Molding? Visit the Injection Molding Zone.

It seems logical that backpressure might raise melt temperature, but as I state in my classes, plastic does not always behave according to my logic. That is why I rely on data. Therefore, after a couple of decades, others have done the experiments and they too found, with better temperature-measurement techniques, that increasing backpressure does not significantly raise the temperature of the melt.

Refer to the data table shown here, which was developed by Mr. David Hoffman of the American Injection Molding Institute (AIM) of Beaumont Technologies. The data in the left side of the table, which has been repeated a number of times (though with only one polymer), shows that increasing backpressure from 50 to 2500 psi (3.5 to 170 bar) with a constant screw rpm does not significantly increase melt temperature. Things may be different for another polymer. The right side of the table shows that increasing screw speed (rpm) provides data that helps explain why so many of us think backpressure increases temperature. The sustained temperature rise shown with increased rpm is much higher than any potential temperature gain from increasing backpressure.

So how does all this relate to the myth that backpressure increases melt tempera- ture? When we make one change on an injection molding machine, there are usually multiple effects. Sorting them out can be difficult, but this one is straight- forward. As a processor, you know that if you increase backpressure, one common result is that it takes longer for the screw to recover—often longer than the set or allowed cooling time. This, in turn, lengthens the cycle time, as the machine does not open the clamp until the screw is at shot size. To get the screw-recovery time back down below the set cooling time to keep the cycle consistent, what do we do? We increase the screw rpm. As the data shows, a melt-temperature increase results when rpm is increased. Hence the confusion of cause and effect.

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com; scientificmolding.com.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreRead Next

Understanding Intensification Ratio

A first step in taking the “art” out of molding.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More.jpg;width=70;height=70;mode=crop)