New Study Refutes Negative Environmental Impact of Plastics Packaging

Packaging has been the favorite whipping boy of environmentalists. But a new report shows that replacing plastic with other materials would have widespread adverse environmental effects.

Packaging has been targeted more than any other segment of the plastics industry. Not surprisingly, since it’s omnipresent. I’ve been around long enough to remember where it all started: in the late 1980s with the hamburger clamshell (which ironically, to my recollection, was replaced by an extrusion-coated wrap). Since then, environmentalists have set their sights on foamed PS, bags, PET bottles (the latest claim is that bits of PET from bottles are getting into the food supply) and lately, straws.

With that in mind, processors and their brand owners might want to check a new study released last month by the Plastics Division of the American Chemistry Council (ACC). Prepared by Franklin Associates and titled Life Cycle Impacts of Plastic Packaging Compared to Substitutes in the United States and Canada: Theoretical Substitution Analysis, the 172-pg study concluded that replacing plastic with alternative materials in packaging applications would cause increases in energy use, water consumption and solid waste, as well as increase greenhouse gas emissions (GHG), acidification, eutrophication and ozone depletion. The report focused on six packaging categories: caps and closures, beverage containers, stretch and shrink film, carrier bags, other rigid packaging, and other flexible packaging

“This report builds upon established data on the energy and GHG benefits of plastics, compared to alternatives,” said Steve Russell, vice president of plastics for ACC. “It expands our understanding of critical environmental benefits beyond energy and highlights key environmental indicators like water use and waste generation.”

The study expands upon a 2014 report that used life-cycle assessment methodology to assess the energy consumption and GHG emissions potential of the same six categories of plastic packaging produced and sold in the U.S. and Canada relative to alternative packaging.

Looking at the U.S. data alone, when compared with alternatives, production, use and disposal of plastic packaging across the six areas studied saves per year:

- Enough energy to fuel 18 million passenger vehicles;

- Enough water to fill 461,000 Olympic swimming pools;

- Waste equivalent to the weight of 290,000 Boeing 747s;

- The acidification potential of 292,000 railcars of coal.

“The findings challenge common misperceptions around plastics and underscore that plastic is a versatile efficient material that is helping to solve some of our greatest environmental challenges. However, we can’t realize its full benefits if we don’t work toward better end-of-life solutions,” said Russell. ACC and North American resin producers established a goal that 100% of plastic packaging will be reused, recycled or recovered by 2040. Meeting this goal and eliminating plastic waste in our ocean will further improve the environmental performance of plastic packaging. “We all want a world without plastic pollution, but we wouldn’t want a world without plastic.”

Call me naïve, but I think the problem most environmental groups have with plastics is emotional. It’s based on fear, and the perception that “Well, if it’s chemicals, it’s got to be bad.” One way to combat fear is with facts. If you serve the packaging market, you might want to download the study and take a look. Try this short URL: short.ptonline.com/ACC

Related Content

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

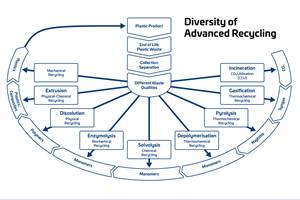

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)