Positive Signs for Appliances

Indicators suggest growth in production of appliances should kick in mid-2017.

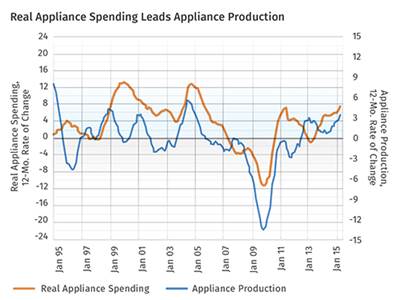

Since May 2012, appliance production has grown in all but about 12 months. This was the strongest sustained period of growth in appliance production since the late 1990s and early 2000s. Through August 2016, appliance production grew at a decelerating rate. What’s in store for the next six to 12 months? The leading indicators help paint a picture.

Real 10-Yr Treasury Rate. The real (inflation-adjusted) 10-yr U.S. Treasury bond rate was 0.75% in August 2016, falling below 1% for the third month in a row and reaching its lowest level since February 2015. Since the Federal Reserve Bank announced it was raising its overnight rate last year, the real 10-yr Treasury rate has dropped in each of the last nine months. A significant reason for this is that the rate of inflation, while still low, has picked up from what it was in 2015. (The real rate is the nominal rate minus infla-tion.) Of course, a more realistic rate of inflation than the Consumer Product Index (CPI) would show that the real 10-yr rate is dramatically negative. The year-over-year change in the real rate was virtually unchanged in August. The change in the real 10-yr Treasury rate was negative for the fourth month in a row, meaning the rate was lower than it was one year ago.

The interest rate is an extremely important indicator for the appliance industry because of its significant impact on the housing market. Generally, a lower rate either encourages refinancing of mortgages, providing cash for home improvements, or it makes the monthly payment for a new mortgage lower, which tends to spur activity in the market. Either tends to lead to purchases of new appliances.

Housing Permits. There were 107,000 housing permits filed in August. In three of the last four months, permits were above 100,000. While the number of permits is still relatively low for the last four decades, the August level of permits was almost the highest since 2007. Compared with a year ago, housing permits increased 10.1%, which was the first month of growth since March. Given the time lag by which interest-rate changes lead changes in housing permits, it very well could be that the rate of growth in housing permits has bottomed and will accelerate for the next six to eight months.

Appliance Industrial Production. Despite the extended period of growth since May 2012, the actual level of appliance production is still at the bottom of the range from 1994 to 2007. That shows what a toll the popping of the housing bubble took on the industry.

In August, appliance production was down 1% from a year ago. That was the first time that appliance production contracted since November 2015. The trend for most of the last year was for weaker growth month over month. As a result, the annual rate of change in appliance production (see chart) has grown at a decelerating rate since March 2015. It’s possible that the rate of change will stabilize for a few months before it decelerates further. However, based on the leading indica- tors, accelerating growth in appliance production should return towards the second half of 2017.

ABOUT THE AUTHOR: Steven Kline Jr. is part of the fourth-generation ownership team of Cincinnati-based Gardner Business Media, which is the publisher of Plastics Technology. He is currently the company’s director of market intelligence. Contact: (513) 527-8800 email: skline2@gardnerweb.com; blog: gardnerweb.com/economics/blog

Related Content

Use Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MoreKrones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreArtificial Intelligence Enables Smarter Sourcing

Westfall Technik has adopted Arkestro’s predictive procurement software to wring savings and more reliable deliveries from a historically challenging supply chain.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreRead Next

Appliance Production Poised for Growth in 2016

Reshoring and an improved housing market explain why.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=970;quality=90)