Despite COVID-19, ERP Software Keeps Molder Working—Even from Home

ERP platform’s remote access, real-time operations overview, and transparency into production output and customer demand help custom molder weather coronavirus.

As an IATF 16949-certified Tier One supplier to BMW, Core Technology Molding Corp., Greensboro, N.C., is required to fully audit its supply chain and have contingency plans in place should there be any disruption. When it was completed, the task represented a box checked on a certification to-do list, but Geoff Foster views the thorough appraisal it required in a different light these days.

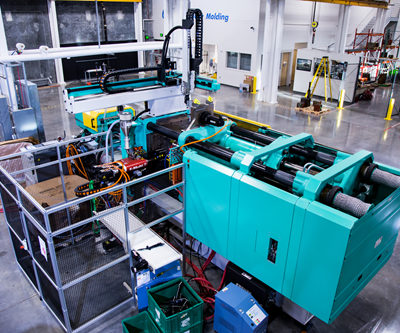

“When we put this together, I never thought we’d have a pandemic, right?” says Foster, Core’s founder, president and CEO. “But now I’m happy that we have these tools in place.” Founded in 2006, Core is a custom injection molder serving the automotive, aerospace, biological pharmaceutical and appliance industries. As the coronavirus wave crashed across the U.S., leaving closed plants and severed supply chains in its wake, Foster says Core fell back on that contingency planning, as well as the remote process monitoring and resource planning software from IQMS (now branded as DELMIAworks following Dassault’s acquisition) to ride out the virus’ tide.

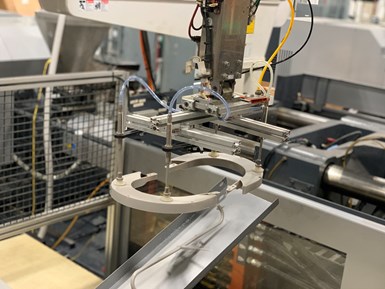

On March 20, BMW announced it would idle its Spartanburg, S.C., facility for two weeks, starting April 3; and shortly after, some of Core’s appliance customers also ceased production temporarily. Core’s operations shifted from 24/7 to 24/5, with some workers furloughed, but designation as a critical business allowed Core to keep its facility running. Eventually, it won a contract for personal protective equipment (PPE); and after building and qualifying two tools in only two weeks, it’s on pace to make 1 million face shields in 2020. Its other business came back online, and production is now back to 24/7.

The production mold and custom end-of-arm robot tool used to pick and place the sprue and parts on the conveyor were turned around in two weeks in this face-shield frame application.

“That planning is what really helped us be nimble,” Foster says, “and we have not missed a beat because of our supply chain. If anything, our supply chain’s become more robust by going through that exercise.”

Full Transparency

Core uses DELMIAworks for everything from scheduling, operations, and purchasing to automating barcoding and labeling. The Warehouse Management System (WMS) keeps track of inventory, scrap and production, and the Real Time module shows live results for key performance indicators like overall equipment effectiveness (OEE) and cycle time to standard. The software touches nearly every aspect of Core’s business, and Core, in turn, is able to touch the software—and its operations—from anywhere, including home.

“You can look at SolidWorks [CAD/CAM software also owned by Dassault]; our IT can remotely see what issues we might be having; quality engineering is able to modify documents remotely,” Foster says, “which is pretty cool, and they had never done it before. It’s one of those things where you don’t know if it can work, but when it does work, it’s really seamless.”

A process technician is using integrated statistical process control (SPC) software, which allows Core to recognize what might be influencing production processes early, allowing preventive measures to be taken.

How seamless? Foster says the range of day-to-day activities that can now be done remotely has led to some confusion about who you might see around the water cooler. “It’s funny, people will come into your office and say, ‘Hey, is so and so here?’” Foster says, “and I’d say, ‘No, he’s at home,’ and they say, ‘That’s what I thought, but he just issued these documents to get approved.’”

No matter how powerful the software, however, it’s still people that make the program, and the plant, run. When Core decided to go with DELMIAworks, it hired a veteran materials manager with 15 years of experience on the IQMS platform.

“Our customers give us a forecast and then our material manager puts that information into DELMIAworks,” Foster says. “When a couple of these customers shut down, that quickly impacted the forecast. If she didn’t really do her due diligence, we would have been sitting on a lot of raw materials and finished goods and quite honestly, that’s cash.”

Related Content

Automation Evolution: From Robots to Work Cells, Solo Devices to Integrated Systems

Injection molding automation has progressed from devices to systems, from simplicity to more complex capabilities. The author traces this development through various levels of automation – all still available choices today – and analyzes the costs and capabilities for each level.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreSeven Automation Opportunities You May Have Overlooked

While not every process is appropriate for automation, the rapid advancement of robotics is allowing a much wider array of businesses access to this technology. Here are some areas where automation makes sense that you might not have considered.

Read More‘Plug & Play’ Machine Monitoring For Small and Medium-Size Processors

New firm aims to bring benefits of real-time visibility of plant operations to smaller plastics firms at modest cost with quick and easy implementation.

Read MoreRead Next

For This Molder, Less Paper + More Data=Higher Productivity

At Tessy Plastics, going paperless means more than idle printers and fewer orders for three-ring binders.

Read MoreMolder Increases Capabilities—But Not Risk—With Flexible Two-Shot Technology

A customer request for multi-material molding presented a market opportunity and potential financial peril: How do you add two-shot without also overextending yourself from an investment perspective?

Read More