The Need for Generalists: Part 1

Expert Advice On Materials

Even companies with seemingly unlimited resources can have problems identifying root causes of problems. Maybe they have too many specialists and not enough generalists.

Periodically, I am asked to speak to groups within an organization who represent the technical support arm of the company. This includes the technical service people, who are on the front lines of the customer complaint process, as well as the analytical department staff that has the responsibility for picking apart the problem back in the laboratory in an attempt to connect the dots and come back to the field people with a resolution.

Recently, I had a conversation with a colleague who had also addressed two large groups within a relatively short time span, one from the material supplier ranks and one at a very large OEM. As we compared notes on our experiences, we noticed a lot of similarities.

First, the people who work within these groups are highly intelligent and extremely knowledgeable in their specific disciplines. Second, the resources available to these people seem almost unlimited. Even if all the instrumentation does not reside within a particular facility, the collective capabilities of the organization to test and analyze are among the best in the world. Third, the communication between the field people and the folks back at the lab is relatively poor. Perhaps this is to be expected because the people at the manufacturing site are typically practical in their approach and make observations that are important to understanding the components of the problem as it presents itself “on the ground.”

If there is a processing issue that involves a particular raw material, the technical service people see firsthand the interaction between the material, the mold, the machine, and the approach that their customer takes to establishing the process. The lab people see none of this and are largely unaware of how these components interact and influence the problem that is being worked on. They are chemists, rheologists, and engineers who have a deep understanding of their piece of the puzzle, but very little aware- ness of the rest of the picture or even the fact that there is a picture. Often the result is that a lot gets lost in translating the problem as it comes in from the field into a strategy for diagnosing it in the lab.

A fourth characteristic that arises directly from this communication gap is a general frustration within the group that they cannot accomplish more. Even with almost unlimited resources and some of the best minds in the industry on hand, many problems do not get solved to the customer’s satisfaction or the root cause(s) are improperly identified. This frustration tends to evolve into a very compartmentalized approach to problem solving. Everyone takes their small piece of the problem as it intersects with their area of expertise, but there is little or no conversation among these experts and no overarching process within the organization to ensure that these experts talk to each other. And this gives rise to the fifth common characteristic. There is almost universal surprise among the attendees at these sessions regarding how far those of us doing the presentations will go to resolve a client problem.

One small example is the use of microscopy to examine a failure. There are various tools within this discipline and no single approach will provide all of the information needed to understand the nature of a problem. Some features are best observed with optical light microscopy while others cannot be seen without electron microscopy. These techniques work best when used together. The optical technique provides an overview and directs attention to the correct locations for the more detailed electron microscopy. A range of magnifications is required to get the maximum value from the work.

But often only one approach is used, a few pictures or images are taken at relatively low magnification, and conclusions are drawn. This can result in an incorrect diagnosis, which then unleashes a series of activities in the field that are considered to be corrective actions. But the problem does not go away.

One of the most common errors related to the examination of a fracture surface is confusing chemical attack with environmental stress cracking (ESC). Both mechanisms involve the presence of a chemical agent. However, in the case of ESC the chemical alone cannot produce the failure; stress must also be present.

Without stress the chemical will not produce the failure, and without the presence of the chemical the stress will not produce the failure. Chemical attack produces failure without any application of stress. The available solutions for correcting the two mechanisms are different. With chemical attack there is a fundamental incompatibility between the polymer and a chemical or chemicals in the application environment. The only way out is to either remove the chemical agents or change the material used to make the part.

But with ESC there are multiple paths that bring in the stress factor. Elevated stress can result from the way the part is being used. But it can also be a product of poor design, such as a sharp corner or a sudden change in wall thickness. It can also be a matter of internal stress caused by processing conditions or it can be induced by an assembly process such as ultrasonic or laser welding. The addition of the stress component to the problem opens up multiple possible paths to solving the problem that can include design improvements, process changes, or the addition of an annealing step.

Several years ago I was involved with a cracking problem on an assembly that appeared after the parts had been assembled and the assembly had gone through a secondary process. The material used to make the part was an amorphous polymer unfamiliar to the processor, who was used to working with polyethylene and polypropylene. The material supplier sent samples back to the lab, took a few pictures, and pronounced the problem to be chemical attack. An attempt to identify the offending chemical was made using infrared spectroscopy. But the matches were not very specific and the source of the general class of chemicals that had been identified was not determined.

A closer examination of the fractures showed that the failure was due to ESC promoted by a welding process as well as some question- ably small corner radii. A deeper dive into the nature of the chemicals contributing to the problem was made using a much more sensitive analytical technique that can identify specific compounds rather than just a general class. Three chemicals of concern were found and were readily identified in a walk through the plant. They were products that had been in use in the plant for many years and had never been thought of as a problem because they do not affect the properties of PE and PP. But they were problematic for this amorphous polymer. Once the problem was properly understood, production of the new components could begin.

The deeper question behind this scenario is, “Why was the root cause missed during the first round of tests?” The equipment that was ultimately used to diagnose the problem was available within the supplier’s lab, as was the talent to use it. As my colleague and I discussed our conferences with these support groups, we came to the conclusion that a big part of the problem was a lack of generalists. Specialization tends to result in a narrow view. But it is a natural process in career growth because it is seen as a strength and as proof of a higher degree of proficiency. But is it really, or is it the problem?

Next month we will dig a little deeper into this question.

ABOUT THE AUTHOR Mike Sepe is an independent, global materials and processing consultant whose company, Michael P. Sepe, LLC, is based in Sedona, Ariz. He has more than 35 years of experience in the plastics industry and assists clients with material selection, designing for manu facturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com.

Related Content

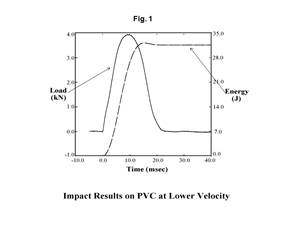

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreTunnel Gates for Mold Designers, Part 1

Of all the gate types, tunnel gates are the most misunderstood. Here’s what you need to know to choose the best design for your application.

Read MoreThe Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreRead Next

Finding Root Causes of a Material Problem

Tools and methods for determining oxidative stability can be useful, but even more useful if constructed to yield the information you really need.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More.jpg;width=70;height=70;mode=crop)