Dosing Basics: How Dosing Works

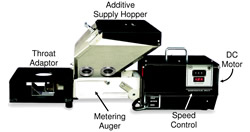

A Doser, or Feeder is designed to introduce minor ingredients to the flow of main ingredients at the throat of a processing machine. Common components include a throat adaptor, DC motor, a metering auger and speed/interfacing control.

Dosing is triggered or speed-governed by the processing machine itself. In injection molding, as the machine cycles, a dose, calibrated to the shot size of the molding machine and amount of additive required is introduced into the gravity flow of the other materials by a rotating auger. In extrusion, as the machine operates continuously, constant dosing is provided at a certain rate, in step with the speed of the extruder.

In some cases, multiple dosing devices may be connected to a single machine throat for the introduction of multiple additives, or simply to provide rapid changeover ease with redundant dosing units already installed. In other cases, other materials, like regrind may be dosed into the flow in addition to or instead of additives. Often times, some form of mixer may be installed below the dosing device to enhance the blending of the newly introduced additives with the base resins.

The dosing device’s throat adaptor is critical to assure:

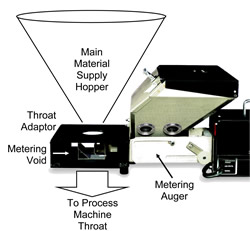

- The ability to support the supply hopper(s) for base resins above it, as well as the dosing unit (typically installed into the side of the support frame) with solid connection to the throat of the processing machine below it.

- The ability to readily calibrate the dosing unit to the additive or material it will be metering. Typically, calibration is accomplished by a catch and weigh procedure to align the performance of the doser to the material it is metering and the rate at which it will be metering.

- The adaptor must create a void in the base material flow through it, so that the dosed additive can readily join the flow of material and not be displaced by its flood feed through the throat.

- The adaptor may be required to allow installation of a mixing unit below it, without sacrificing structural integrity. In some cases, the mixer’s housing can provide for the installation of a metering device directly, without the need for the dosing device’s throat adaptor.