Blender Troubleshooting

1. Check the electrical installation of the blending device. Even if the system worked well for a time, especially dry or wet weather or increased plant electrical noise can cause new problems. Note that voltage spikes, electrical noise and improper grounding are common problems for sophisticated control equipment, like blenders.

2. Follow the checkout procedure for the blender (if provided) to assure the blender’s basic operating parameters are functioning correctly. If anything does not work correctly, address the diagnostics of that particular function.

3. Similarly, re-acquaint yourself with the normal operating sequence to be sure you understand what the blender is supposed to be doing at each stage of operation.

4. If provided, read the list of typical problems or FAQ’s supplied by the blender manufacturer.

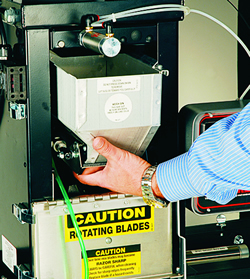

5. Look for material blockages, bridging or build-up that may foul the normal operation of the blender, including the load cells on gravimetric models. Clean thoroughly as needed.

6. On gravimetric units, re-verify load cell function to be sure that the delicate load cells are not damaged and are operating correctly. Typically, a test or procedure for this is included in the manual.

7. Determine that the capacitance sensor(s) on the unit are functioning properly. Often, the sensitivity of a sensor sensor will change due to material dust buildup on the sensor and requires either cleaning or re-calibration.

8. Examine the unit for obvious mechanical failures: Air solenoids, cylinders, motors, sensors, etc. Be sure these items are plugged in and able to operate (they are often unplugged for cleaning or when equipment is moved).

9. Clear the memory of the blender to ‘start from scratch’ to remove unwanted program changes that have been added over time.

10. Discuss the issues with the manufacturer and, if equipped, provide a print-out from the blender, for as long a period as possible, to help the manufacturer diagnose potential problems.