Volumetric Blender Preventive Maintenance

Blenders are often subjected to long hours of use and sometimes abuse. Volumetric blenders cannot match the accuracy of gravimetric blenders but blending accuracy still has to be monitored and maintained to ensure that the expected level of accuracy is maintained. To maintain control over the cost of expensive material and additives, it is recommended that blenders be examined no less than once a year, and that preventative maintenance is ongoing to insure expected accuracy.

Dump Gates/Valves

Material valves must open and close freely. Check for wear on slide gate guides. Check the cylinder positioning adjustments for correct closing of the gate. A valve should close just enough to block the flow of material, but no further. Depending on the nature of the valve or gate, it is best if they do not pass over the far edge of the material opening as this might catch and jam on a pellet. Check that the clevis pin connecting the air cylinder is intact, not broken or worn through. Check for correct air pressure, tight fittings, and no damaged or crimped air lines.

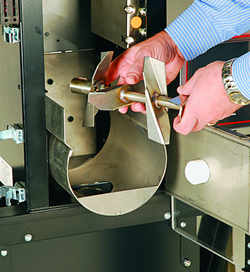

Mix Chamber

Check for bent or significantly sharpened blades, created by material abrasion from mixing. Bent blades could break off and severally damage your process screw. Sharp blades are a safety hazard and provide increasingly poor mixing performance. Replace the mix blades if they are not in perfect condition. The mixing blades typically unlock and/or slip on and off the drive system easily for cleaning. The need to use excessive force to remove the mixer assembly may indicate extreme wear and/or contamination and/or defective mechanical components, like the locking mechanism or the interlocking motor shaft collar. This should be corrected to prevent broken blades and creation of a safety hazard.

Metering Augers

Many volumetric blenders use augers to meter material and/or additives into the mixing chamber. Each auger should be checked for smooth rotation and rapid response of the drive motor when called upon to meter material. Over time, severe wear of the auger can occur from material abrasion and it must be replaced to assure continued accuracy and to prevent a safety hazard from sharpened auger flights. Similarly, the auger housing may suffer from abrasive material wear and also require replacement. Check the connection between the drive motor and the auger to assure that the mechanical link between them is intact and not significantly worn.

Vibratory Feeders

Some volumetric blenders utilize vibratory feeders to meter materials and/or additives into the mixing chamber. Each feeder tray should be checked for constrained movement and rapid response from the drive system when called upon to meter material. Over time, wear of the vibratory tray suspension can occur, radically changing the accuracy of the metering process. The need for frequent re-calibration and/or elevated noise levels are good indicators of suspension wear. The drive system should also be checked to assure that it is still providing ample tray movement for the metering process, at consistent rates.