Controls for Blenders

See how easy it is to enter blending data with this example of a modern blender control.

The impressive advancements in control technology for industrial equipment have not been overlooked in the latest generations of controls for automatic blenders. Acknowledging that the dialog between man and machines that blend resins and additives can be confusing, blender manufacturers have strived to reduce the inputs, computations and specialized knowledge required by the user to a minimum. Today’s blenders do the thinking for you. All the user has to do is to input the desired variables, and the control does the rest.

Here are some examples of typical blending controls:

PLC:

Many manufacturers have entered the blending market utilizing ‘off-the-shelf’ programmable logic controls, due to their flexible design capabilities. The growth in popularity of PLC’s in industrial applications has generated a multitude of interfaces for the PLC user, ranging from detailed I/O programming, requiring special skills and equipment, to touch screens, requiring only rudimentary knowledge of the blender operation.

In general, PLC’s perform the functions required for blending adequately and buyers are often comforted by the historic reliability of this class of product. However, PLC abilities in weight readings and fast responsiveness are often not suitable for today’s full featured, sophisticated and highly accurate blenders. In addition, being a generic control device, the PLC must be custom programmed extensively for blending applications and the functions required often demand a very high premium price in I/O and a fairly large control cabinet size. Touch screen controls for PLC driven blenders have made the products relatively easy to use, but typically lacking in the depth of their features and response speed, and as a result, the accuracy of the overall product.

Proprietary Controls:

Many manufacturers have concluded that in order to perform the functions required of a sophisticated blending device, the controls must be created from scratch and be dedicated to the functions of blending. Such controls are optimized for all of the functions of time, weight readings, number of inputs and outputs, etc. and are designed to be instantaneous in their operation, for speed and accuracy of blending. Using this approach, proprietary controls for blenders are typically ‘loaded’ with features not found on PLC’s and they can typically be modified readily via simple software changes; not add-ons nor new firmware. Adding reliability to the list of ‘must-haves’ for these proprietary controls makes them the logical choice for today’s buyer and today’s full featured blenders.

A number of user interfaces are available for custom designed blender controls:

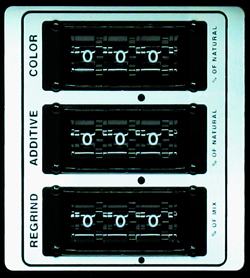

Thumbwheels: Reducing the number of inputs that must be provided by the user (allowed by the sophistication of the controls themselves) has led to the offering of thumbwheel input switches that require the user to only input the percentages of each ingredient desired. This interface methodology is intuitive and simple and literally, the control does the rest. Unless the user wishes to change other basic parameters, IE: blending time, the type of metering device being used, etc., once inputs are provided via the thumbwheels, an “ON” switch may be flipped to begin blending.

Thumbwheels are typically provided for the more basic models of blenders, combining up to 4 materials.

Keypads:

Users wishing to store their blend combinations, or for larger blenders that combine more than 4 materials, will benefit from blending controls with keypad entry. These simple labeled buttons tap into the brains of the control and allow more sophisticated access to the operation of the blender. A small multi-line display, menus and selection codes are common and although they are not as simple to use as thumbwheels, the keypad control method unlocks deeper functions, recipe storage, operational variations, etc. Some popular blenders utilize both thumbwheels and keypads for multiple levels of sophistication and commonly, multiple levels of user access; IE: everyday or engineering level.

In an attempt to simplify the user experience with blenders, manufacturers have taken advantage of the latest advances in touch screen controls and the public acceptance of them. Touch screens can provide not only simplified input logic, like thumbwheels, but also exhibit pictures and allow for deeper access to the blender when needed; all on one screen.

The range of use of touch screens is extensive.

Some mimic the popular thumbwheel concept by sporting images of thumbwheels that may be manipulated on the touch screen. User acceptance is instantaneous and the intimidation level is very low for everyday users. Yet the same screen can convert to more sophisticated use with a simple touch of another area of the screen.

Other manufacturers employ central images on the screen, allowing the user to select what item (mixing chamber, metering device, etc) they wish to control. Once selected, that portion is either highlighted or expanded for more control choices.

thumbwheels for ease of use