Is Dosing Good Enough, Or Do I Need A Blender?

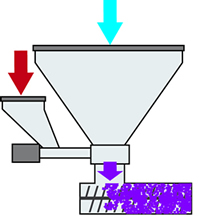

Dosing can be described as the introduction of a specific material ingredient, like color concentrate, to an otherwise independent flow of material, into the process.

One standard example of dosing is a simple feeding unit on the throat of a process machine, metering color concentrate or liquid color into a flow of virgin material, supplied from a hopper above the throat. As the virgin flows to the process, colorant is metered into it. Other additives or even regrind can be metered as well.

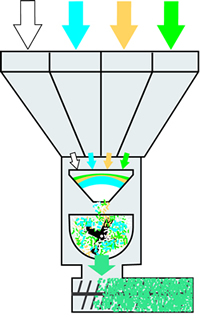

Blending, on the other hand, controls ALL of the ingredients flowing into the machine throat, not just the dosed additive. In fact, blenders are actually made up of multiple dosing units, some coarse and some fine, working in conjunction with each other by time or weight to create the precision introduction of all materials to the process. In addition, a blender typically includes a mixing section so that all of the metered ingredients are mixed thoroughly to assure a homogenous blend flowing into the process.

A common blender application might include the metering of virgin material, by a pneumatic gate valve, plus regrind material, also introduced by a gate valve. These two main ingredients of a blend might be joined by an auger doser, metering in color concentrate in a precise proportion to the virgin (not regrind) material. All three precisely administered materials are blended together in a mixing section, resulting in a highly controlled, repeatable recipe flowing to the process.

Dosing is an adequate solution for joining materials as long as the processor understands that only ONE ingredient is under control. Only one ingredient is being dosed. The other materials(s) are flowing into the process on their own. Hiccups that commonly occur to the main material flow, like material consistency variations, clumping, bridging, or even lack of material replenishment will affect the accuracy of the dosing.

See Comparing Blending Alternatives for an explanation of volumetric vs. gravimetric dosing and blending.

For the highest precision, fully complimented, multi-material gravimetric blenders are the best solution. Placing precise control over all of the ingredients flowing into the process assures that under nearly all conditions, a precise, repeatable blend flows into the product.