Gravimetric Blender Preventive Maintenance

Blenders are often subjected to long hours of use and sometimes abuse. Blending accuracy can suffer as a result. To maintain control over the cost of expensive material and additives, it is recommended that blenders be examined no less than once a year, and that preventative maintenance is ongoing to insure continued accuracy.

Dispense Gates and Valves

- Material dispensing gates and valves must open and close freely, quickly, and completely.

- Check for wear on slide gate guides. Check the cylinder positioning adjustment for correct closing of the gate.

A gate or valve should close just enough to block the flow of material, but no further. Depending on the nature of the valve or gate, it is best if they do not pass over the far edge of the material opening as this might catch and jam on a pellet.

- Check that the clevis pin connecting the air cylinder is intact, not broken or worn through.

- Check for correct air pressure, tight fittings, and no damaged or crimped air lines.

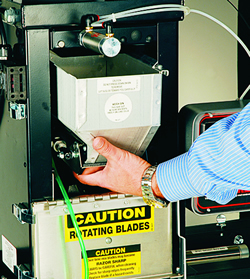

Load Cells

Do not remove the load cell from its mounting, but disassemble it (IE: remove the back cover) to allow inspection for contamination that may have entered and built up over time.

- Blow out any contaminants with compressed air.

- Based on the dustiness of the materials you typically process, load cell contamination may be an ongoing issue for your blender and a more refined load cell enclosure may be required from the manufacturer.

- Although slight, free movement of the load cell is critical and material build-up cannot be tolerated.

Gain-in-Weight Bins

- Check for smooth operation of the discharge valve, flap or gate.

- The pivoting points of these mechanisms should not be worn.

- The valve device should not allow dribble when closed, even when closed against pellets.

- The valve mechanism should accommodate the static build up of pellets without interfering with the stoppage of material flow.

- Check that the valve closes fully.

Free Movement of Weigh Bin

- Carefully examine all parts of the weigh bin and its support bracket(s) to be sure that nothing touches any fixed part of the blender and its weight is fully supported by the load cells, as it was designed.

- Clearance should exist on all sides of the weigh bin to prevent inaccurate weight measurements.

- A light touch on the bin should show a change in the weight readout on the control. Removing the touch should return the display to exactly the same number, plus or minus 1 or 1/10 gram.

- Typically, depending upon the manufacturer’s display accuracy, only the last digit should drift, or vary, and by no more than one count.

- If any interference of the weigh bin is detected, it must be fixed.

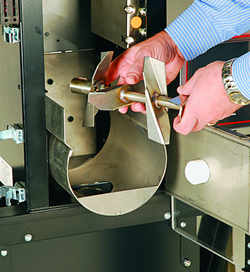

Mix Chamber

- Check for bent or significantly sharpened blades, created by material abrasion from mixing. Bent blades could break off and severally damage your process screw.

- Sharp blades are a safety hazard and provide increasingly poor mixing performance.

Replace the mix blades if they are not in perfect condition.

- The mixing blades typically unlock and/or slip on and off the drive system easily for cleaning. The need to use excessive force to remove the mixer assembly may indicate extreme wear and/or contamination and/or defective mechanical components, like the locking mechanism or the interlocking motor shaft collar. This should be corrected to prevent broken blades and creation of a safety hazard.