Two-Stage Injection Unit

Extruder and injection Drives

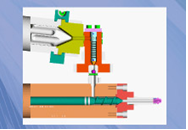

Melt Cross-Over

Melt Cross-Over Diagram

POWERLINE - 2 Stage Injection

Two Stage Injection Unit for High Throughput Applications

- Shot size from 30 oz (35,000 psi) to 195 oz (17,800 psi)

- Shot size versatility: 2% to 95% shot capacity

- Improved residence times by varying extruder diameter without affecting shot size, rate, or pressure.

- Separate plasticizing and injection functions. Adds molding capability and flexibility.

- Generates higher injection rates, pressures and volumes with smaller, more precise electromechanical drives.

- Long stroke for improved resolution and repeatability.

- Improved melt quality: Consistent L/D; each pellet sees same heat and screw length.

- Ultimate screw versatility: GP; Powermelt TM Barrier; Wear star; Barr ET; Barr VBET; Klearstar; and engineering material capable

- Up to 1200 lb/hr throughput capability.

- Adaptable extrusion-to-injection technology such as screen changers and compounding.