Open Array Fantail Manifolds

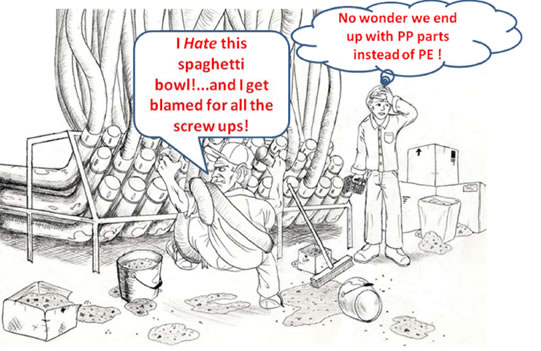

Fantail manifolds are designed to present materials from a number of different sources in a relatively compact space so they can be connected to a material line that will convey them to their assigned destination. The basic idea is that a worker manually connects a flexible material destination hose to a material source line on the manifold. The hose is held in place by an auto-lock connection. Typically, the connector on the flexible hose is marked with a machine number and the cap on the fantail manifold is marked with a material designation. Still, this can be a tricky business. The area around an open array manifold with maybe 30 or more flexible hoses hanging down, is often referred to as ‘the spaghetti bowl’ and a mistake here can cause havoc on the production floor. The confusion is multiplied when an “open array manifold” is used because the hoses can get tangled among the manifolds.

Things to look for with any manifold system:

- Auto lock connections – to ensure that once the connection is made, it stays put

- Upright manifold lines – promotes improved purge performance

- Modular, expandable design – so additional materials/machines can be handled

- Purge capability – to minimize contamination of material