100% Recyclable PET Vies to Replace Composite Cans

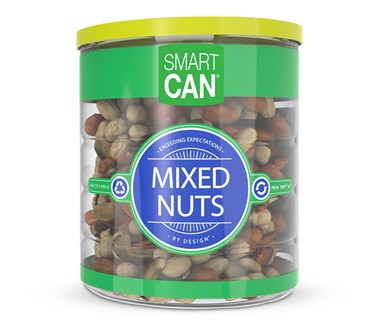

Ring Container Technologies, Oakland, Tenn., a blow molder of HDPE and PET packaging, announced the first customer for its new SmartCAN, a PET can designed to replace the common composite can with a much more easily recyclable alternative at comparable cost.

Ring Container Technologies, Oakland, Tenn., a blow molder of HDPE and PET packaging, announced the first customer for its new SmartCAN, a PET can designed to replace the common composite can with a much more easily recyclable alternative at comparable cost. John B. Sanfilippo & Son, Inc. (JBSS), Elgin, Ill., whose brands include Fisher Nuts and Orchard Valley Harvest, has chosen SmartCAN for its dry snacks. The all-PET container replaces a composite can composed of paperboard with an aluminum foil interior facing and two metal ends.

SmartCAN is made by two-stage stretch-blow molding, with a dome on top that is trimmed off, a technique Ring Container has used on other products as a cost-effective means of making a wide-mouth container. The can is topped by a peel-off lidding foil (applied by the customer after filling) and by a snap-on HDPE lid (a screw-on version is available). The customer also provides the wrap-around label. The can has a slightly domed bottom, which provides stability during conveying. The can is designed to resist “paneling” deformation if filled with a warm product, says Cory VanLoocke, director of sales & business development. He also notes that SmartCAN is 35% lighter overall than a composite can of the same size (38.5 g vs. 59 g).

Ring Container Technologies previously supplied JBSS for years with PET wide-mouth jars as snack containers, but SmartCAN is the company’s first “drop-in” replacement for composite cans, that’s adapted to existing filling lines. As noted by Tim Ferrel, v.p. of business development, SmartCAN addresses consumers’ and brand owners’ growing interest in recyclability and it also has the advantage of transparency, allowing the consumer to view the package contents. SmartCAN is currently available in two standard sizes—401 x 411 and 401 x 406 (30.5 and 28.6 fl oz, respectively)—though others will be available in future. What’s more, the PET can is customizable both in size and shape—“It doesn’t have to be a simple cylinder, unlike a composite can,” says Ferrel.

Ferrel sees numerous opportunities for SmartCAN beyond dry snacks, such as dried fruits and instant foods. Though the can is currently produced at two locations, it could in future be made at any of the company’s 19 “focused plants” in the U.S., Canada and U.K. It does not require special production machinery, only tooling.

VanLoocke adds that the PET can could potentially incorporate up to 50% post-consumer recycle (PCR), enhancing its environmental advantages. He notes that a lifecycle analysis (LCA) performed by an independent third party (using the COMPASS LCA software tool) shows that SmartCAN produces 42% less greenhouse gas emissions using virgin PET, and 50% less with addition of 30% PCR, than a composite can of the same size.

VanLoocke and Ferrel both note that the company is committed to sustainability throughout its operations and just this year joined the How2Recycle program of the Sustainable Packaging Coalition, becoming the 200th member of this North American group. As a result, Ring Container labels will now contain instructions for consumers on how to prepare the empty package for recycling (such as inserting the lid or rinsing the container); identify the types of materials used and which parts are recyclable; and inform consumers whether those materials are recycled widely or in limited capacity.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)