Absolute Haitian and iMFLUX Partner

The distributor of Haitian injection molding machines in the U.S. and Canada has partnered with the P&G subsidiary to bring iMFLUX’s low constant-pressure molding platform to the market.

Absolute Haitian (Worcester, Mass.), the sole distributor of Haitian injection molding machines in the U.S. and Canada, and iMFLUX, a subsidiary of Procter and Gamble, have signed a distribution agreement to integrate iMFLUX processing software as an option on Haitian servo-hydraulic and Zhafir electric injection molding machines.

iMFLUX’s low constant-pressure molding platform automatically recognizes changing process and material conditions and adapts in real-time. Utilizing iMFLUX, molders can run an array of materials, including post-consumer recycled content (PCR), with less energy, wear and waste.

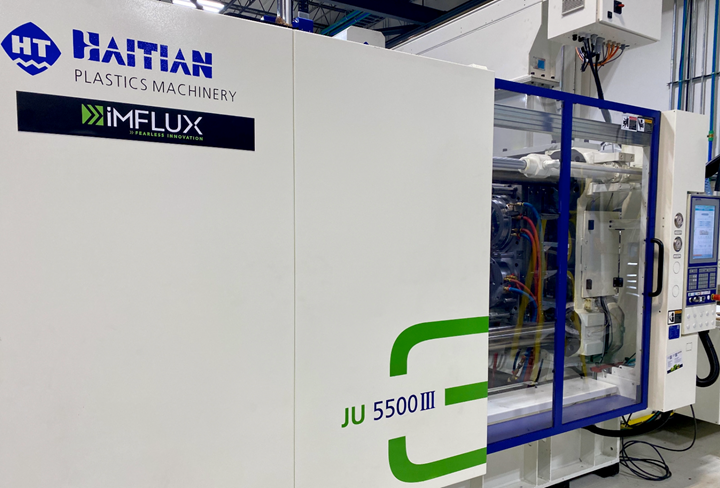

At virtual events held by iMFLUX (on May 25) and Absolute Haitian (on June 10), the companies will demonstrate iMFLUX technology on a 618-ton Haitian Jupiter III two-platen, servo-hydraulic press. The JU5500 III will run a four-cavity housewares family mold—two bowls, four spoons and a lid—made from recycled polypropylene. The machine cell integrates automation featuring the Hilectro servo robot and Fanuc collaborative robot.

In 2018, the iMFLUX announced the integration of its technology on select Milacron injection molding machines.

Absolute Haitian will now make iMFLUX low constant-pressure injection molding technology available on select machines for sale in the U.S. and Canada.

Related Content

-

Are Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

-

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

-

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

.png;maxWidth=300;quality=90)